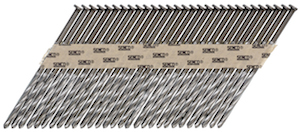

SENCO Stainless Steel and Aluminum Nails

When fastening, users need to consider the environment and the specific wood type in order to choose the correct fastener type and finish to avoid corrosion and unsightly staining of the work surface.

When fastening, users need to consider the environment and the specific wood type in order to choose the correct fastener type and finish to avoid corrosion and unsightly staining of the work surface.

Plain steel fasteners are especially susceptible to rust and corrosion over time when exposed to moisture. The corrosion process accelerates when fasteners are exposed to salt air near the coast and when installed in preservative-treated lumber.

SENCO has introduced 22 new nails. These nails include a wider offering of 304 stainless steel, new 316 stainless steel, and new aluminum nails in four collations including zero degree plastic coil, 15 degree plastic coil, 15 degree wire weld coil, and 20 degree plastic strips.

316 stainless steel nails allow for superior corrosion resistance particularly in areas near the coast where fasteners are often exposed to the harshest environmental conditions. Aluminum nails are ideal for soft woods, particularly cedar and redwood.

Aluminum helps eliminate staining, bleeding, or streaking that can occur when using galvanized or plain steel fasteners.

Used in a variety of applications from siding, fencing, decks, docks, to general exterior construction, these 22 new nails further shows the completeness of SENCO’s fastener offering. Visit www.senco.com/specialty-fasteners for additional information.