|

Building Better Relationships Safely

Every business up and down the road buys or needs something that Verona Safety Supply sells, even if it is as simple as a first-aid kit for employees.

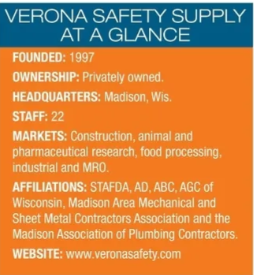

Since 1997 the Madison, Wisconsin- based company has kept people safe across multiple industries. It was at age 28 that Verona Safety President David Anunson saw something in the fledging safety distributor that started in Sue and Doug Groy’s garage.

“Growing up I always had a mind to do my own thing,” he says. “While working for another company my entrepreneurial side kicked in and I figured if they could do it, I was capable.” The mindset was there but at least to start with, he lacked a solid understanding of what it would take to operate a business, and get past cashflow and debt to make money.

Following a lunch with Sue at which he inquired if she wanted to ramp up the business, Anunson developed a business plan. In 2001, Verona Safety went from being a sole proprietorship to a partnership between the Groys, Anunson, and Mark Larsen. The foursome worked together, serving as salespeople in the morning, working warehouse and shipping in the afternoon, and then as purchasing agents in the early evening.

“I was a young man in debt, 28 years old, with a beat-up Ford F150 pickup, so getting that line of credit took a lot of work,” Anunson says. “When you’re 28 or 29, you’ve got all the cockiness in the world. You don’t think about failure. It never even occurred to me that it wouldn’t work out. Now I look back and think, how did I do that?”

|

|

Sam Gossfeld, VP of sales; Greg Keyes, VP of operations; David Anunson, president/partner; Jason Schaefer, VP of accounting/partner. |

After visiting multiple banks, one finally took a chance and gave the young company a $70,000 line of credit which allowed them to buy inventory and move from the Groy’s garage to lease warehouse space and a small office in Madison, which was more affordable than Verona.

Despite the separation of physical location, the City of Verona is still a key piece of Verona Safety’s history due to the amount of business that would ultimately develop from the construction of Epic Systems Corporation’s campus headquarters in the Madison suburb. Recognized worldwide as a Wisconsin landmark, the Epic campus was something Madison had never seen before.

“We went to that jobsite and started earning pieces of business,” Anunson says, noting that it was a recognition of construction being a high-risk job and the potential opportunity for sales.

“That is kind of part of our whole history, is the relationships that we create, we hold on to,” Anunson says. “It just became a relationshipbuilt company.”

In March 2004, Jason Schaefer became the latest corporate member, bringing a master of accounting and helping to ensure the company’s financial i’s and t’s are always dotted and crossed.

Verona Safety catapulted from doing $200,000 annually to $1.1 million in its first year under the partnership. Sales have continued to increase annually for all but two years since then.

Initially, nearly 50% of Verona Safety’s business was on disposable PPE for the pharmaceutical and animal research and food processing markets, such as nitrile gloves. Now, that accounts for only about 10% to 15% of the company’s business with nearly 60% being accounted for in the construction market, which has grown considerably as safety regulations and requirements have advanced in the past 20 years. The remainder of the business is in industrial and MRO.

For direct shipment on Verona Safety’s trucks, the company serves about a 100- to 120-mile radius.

General shipping is available worldwide. The company’s typical area of influence depends on the market. For construction, most customers are within that 100- to 120-mile radius but for disposable PPE it’s more nationwide.

“Every customer is an important customer,” Anunson says. “We can get your guys safe for whatever budget you’re in.”

Maintaining a strong presence within multiple industries, Anunson believes Verona Safety still needs to build up even more brand recognition.

“I’ve still got customers that say, ‘I’ve always ordered from Dave’ and I need that to be less Dave and more Verona Safety so it’s the right brand,” he says. “We’re making that change, to be a brand, to be an actual full-on distributor, and not just a bunch of really smart safety guys that can help you.”

|

| Steve Morin, jobsite inventory manager, is pulling product for a vending machine order. |

BONDS OF BUSINESS

With more than 25 years of experience, the phone keeps ringing at Verona Safety because of the longevity and expertise of the entire staff.

“Being able to do that with all the manufacturers we work with is more valuable to our clients than a single manufacturer telling them that they have everything they need because they don’t,” Anunson says. “There isn’t a single manufacturer in the world that has everything everyone needs to make sure their workplace is safe.”

From his point of view, Verona Safety is able to bring all those options to the table when discussing options with a client.

However, the challenge for the company has been to be ready to continually adapt to the changes in the distribution model. When the company was founded, safety suppliers or manufacturers would take care of safety distributors, often granting a certain amount of exclusivity based on geographic location. Today, several manufacturers have opened the door to anyone who wants to sell their products.

“Manufacturers were so hungry for growth that they weren’t getting through organic growth, so they just decided to try to take a bigger bite of the apple,” Anunson says. “Today, if you wanted to start a safety distribution company, probably a third of the vendors we work with would set you up.”

Being relationship-focused on both the supplier and client side of the business has eased the pain for Verona Safety to an extent. More than a dozen suppliers the company works with dates back to 2001. The relationships and connections with people who are still at those companies continue to be fruitful as both they and Verona Safety have grown together.

Beyond its own actions, Verona Safety also reaps the benefits of working with buying groups such as AD. With a focus on small to mid-size distributors, AD uses the volume of multiple members and branches to negotiate better prices with the manufacturers and suppliers.

“That’s certainly helped us because some manufacturers simply do not care,” Anunson says. “Our rep cares, and a few people within that organization might care about the people here but that corporate entity doesn’t care who buys a respirator, or where they’re getting it from.”

Even if Verona Safety doesn’t always win that discussion, Anunson is confident the overall distribution model isn’t going anywhere.

Most of Verona Safety’s suppliers continue to follow the distribution model, although there are a few that have taken to selling directly off their websites. However, it is the manufacturers who add a “buy now” button on their websites which are linked directly to a select three or four online distributors which can harm Verona Safety more. To Anunson, the challenge is just another example of where better relationships can come into play.

|

| Verona Safety Supply President David Anunson says "Every customer is an important customer. We can get your guys safe for whatever budget you're in." |

“We must keep our eyes open and make sure our relationship with that end user or client is strong enough so the end user tells the manufacturer that they’re getting the product from Verona Safety,” Anunson says. “You have to kind of vet out who you can trust and who’s not going to step on you.”

Ultimately, a bigger onus is put on Verona Safety to ensure their clients understand what they offer is far more than just products.

“We must continue to earn the business,” Anunson says. “It never stops.”

LABOR OF LOVE

From a staff perspective, the number one priority at Verona Safety is that every employee is expected to have a basic understanding of the available products. Even warehouse staff are included in vendor training meetings, so they are more familiar with the products they are handling.

“Don’t just give someone part numbers and prices,” Anunson says. “When you’re new, you’ve got to, but it is incumbent upon us to make sure that individuals who are valuable to us at Verona, we’ve got to educate them so that they’re more valuable, not only to us but to the customers.”

Similarly, as part of the company culture, everyone is given a greater understanding of what all facets of the company is involved with to ensure more respect and understanding amongst the staff.

“A salesperson might not respect what that warehouse picker is doing or what their day looks like,” Anunson says. “If you understand that, you have some empathy, and you work together, and hopefully you move forward with a little more efficiency and certainly a better attitude.”

The concept is part of the company’s basic core values which are: honesty, hard work, always smiling and always treating people with respect.

Finally, Anunson stresses that staff should never tell a client or customer “No.”

“Figure out how to get that business,” he says. “If you’ve made a promise that you can’t keep, get on the phone with the customer right away and let them know. It’s the same things people should be doing in life, right? It’s easier not to be a jerk if you choose not to be.”

|

| Verona Safety Supply ships its SKUs across the nation to clients in various industries. Once picked from the warehouse each order is verified before breing packed and shipped. |

Among customers, there is always a high expectation of a rapid followup from Verona Safety. Typically, return calls are made within a day, pending the depth of the question.

Also, based on a trait Anunson picked up growing up around dairy farms, most employees make themselves available even during off hours in the event of a customer emergency.

“If someone was out baling hay and you were driving by, you’d swing in and help them unload the wagon,” Anunson says. “Here, I don’t expect you to be available, but if you choose to be available, it can enhance what we’re doing.”

He credits the success of the company to his employees. Anunson likes to believe that all 22 employees care about and are part of Verona Safety’s success because it is part of their success.

“It’s always been important to me, that we all want this company to do well, and if it does well, we’re all going to be okay,” he says.

INTO THE FUTURE

|

Having built a strong operation at its current location, Anunson says there is no question Verona Safety needs more space, emphasizing that any move would keep the company based in the Madison area.

“Having the space will give us the ability to order and store a little more efficiently, which translates to being able to make it easier to sell products in the field,” Anunson says.

In addition, provided that enough business can be generated, there is a potential for Verona Safety to expand its geographic footprint with additional branches. Anunson says they will not invest in that process unless the numbers show there is enough business for it to make sense.

“We’ve dialed in that we are out there helping protect your employees, but we’re also the company that could sell you a hammer,” Anunson says. “Once a customer knows that they’re likely to pick up the phone and call us first.”

Zac Matthias was hired as marketing manager in 2014 to adapt and update the company’s online and social media presence to today’s methods of communication. The way 25-year-olds engage today is different than the way Anunson and his partners and the clients engaged 25 years ago.

“We engage by calling or stopping in and they engage first on Facebook or wherever they can find you on Google,” he says. “I don’t love the way the business world has gone, but as a business, you adapt.”

Like most small to mid-sized distributors, Verona Safety gets offers annually from venture capital investment firms and larger companies looking to make acquisitions and expand their overall reach. For now, Anunson prefers that Verona Safety be the “small guy.”

Though he won’t be around forever, Anunson’s goal is to continue the legacy of Verona Safety.

From a leadership perspective, both Greg Keyes, vice president of operations, and Sam Gossfeld, vice president of sales, are on track to take his vision of the company into the future and beyond. The pair are ready to merge the company’s legacy of industry knowledge with a younger generation’s twist of doing things that will be required to grow and attract new talent as they focus on making Verona Safety a full-service distributor.

“I like winning against big companies and I want Verona Safety to continue to do that,” Anunson says. “That’s part of the reason I still like coming to work. Part of what I enjoy about our team, is when we win, Fastenal or Grainger loses. I like beating those guys in the field, so as long as I’m breathing and healthy, that’s where I want to see Verona Safety, and that means not selling out and working towards a plan where the employees can accrue ownership.”

This article originally appeared in the February/March 2025 issue of Contractor Supply magazine. Copyright, 2025 Direct Business Media.