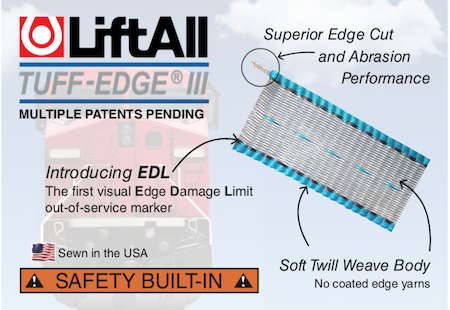

Lift-All Tuff-Edge III Slings with EDL

Lift-All Co. the trusted name in lifting and load securement products is pleased to announce the upcoming launch of its 3rd generation Tuff-Edge webbing. Tuff-Edge III has three patents pending and is the result of two years of hard work and design perseverance.

Lift-All Co. the trusted name in lifting and load securement products is pleased to announce the upcoming launch of its 3rd generation Tuff-Edge webbing. Tuff-Edge III has three patents pending and is the result of two years of hard work and design perseverance.

“We did not want to develop another product with coated edge fibers. Our customers did not like being poked in the hand if the edge became frayed or cut. We wanted to offer a solution and I believe that we did just that,” said Steve Pacilio, President of Lift-All. “We listened to our customers and designed a product that would be soft and pliable and have improved edge damage resistance.”

The number one reason to remove a sling from service is edge damage. The newly designed Tuff-Edge III includes a tubular edge with damage resistant core fibers which float inside to aid in preventing damage to the body fibers. This keeps the integrity of the sling intact without compromising its strength. In fact, Tuff-Edge III is 30% more resistant to edge damage than the current Tuff-Edge II webbing. The body weave design was also changed to incorporate a twill weave which helps improve abrasion resistance and allows the sling body to remain soft and pliable.

The most unique change to the web is the revolutionary EDL (Edge Damage Limit) indicator which is a black marker yarn that runs along each edge. If there is a cut or damage to the sling edge, the sling can remain in service as long as the damage has not reached the EDL marker, assuming the rest of the sling is in good condition.

“The EDL is the first of it’s kind in the industry,” said Greg Babinchak, Manager of Technical Services for Lift-All and Chairman of the Web Sling and Tiedown Association’s Roundsling Committee. “Sling inspections are difficult enough and this out of service tool is a welcomed and beneficial safety feature of our Tuff-Edge III webbing. It provides our customers with a visual guide to help them understand when they should remove the sling from service due to edge damage.”

Lift-All Co. is celebrating 55 years of engineering solutions for the lifting and load securement industry whose markets include construction, manufacturing, oil & gas, wind power and entertainment. With a team of Customer Service Specialists and dedicated District Salesmen covering North America to provide solutions, training and assistance with sling inspections, you can trust Lift-All to be there to help you get the job done safely.

For more information visit www.lift-all.com.