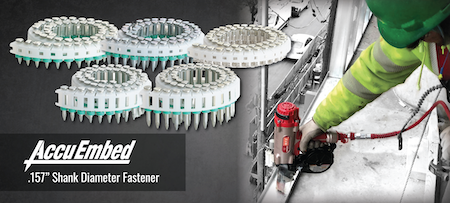

MAX USA AccuEmbed .157-Inch Pins

MAX introduces the AccuEmbed .157” pin to the commercial marketplace, delivering a more dependable fastener, while also giving contractors the confidence of carrying out work with measurable specifications.

MAX introduces the AccuEmbed .157” pin to the commercial marketplace, delivering a more dependable fastener, while also giving contractors the confidence of carrying out work with measurable specifications.

In response to the markets need of .157” pins for the PowerLite system, but also identify how these applications are utilized with end-users, MAX Co, Ltd., developed the AccuEmbed line of pins.

Understanding the use of P.A.T. tools by only licensed users, time constraints, the high costs, and inefficient stick-rate of each shot, MAX looked at how these fasteners could be integrated with the MAX PowerLite High Pressure tools for enhanced use in the field.

In pursuit to consistently deliver reliability in the field, through innovation, the R&D team at MAX worked to identify key benefits, cost savings, and efficient operations missing in Powder Actuated Systems (P.A.T.).

“Understanding the issues contractors are facing in using .157” pins for P.A.T. systems, our team developed the AccuEmbed pins with an extra shank length of .079” that provides accurate embedment depth for structural exterior metal track fastening into concrete or steel I-Beams in commercial buildings," said Yuta Asaba, Product Specialist.

"The additional length of the pin taking into account material thickness provides the user more pin embedment and stronger pull values. Being able to integrate these pins into our HN120 tool, we are able to provide 50 collated pins in a plastic sheet coil compared to traditional single shot or 10 round P.A.T. designs. End-users can focus more on the work at hand and spend less time and money on having to reload and properly dispose of powder-actuated cartridges, which carry costly fines if not properly disposed of.”

The performance of the AccuEmbed pins have been confirmed by the ICC-ES in report ESR-4320. Even just having been recently released into the marketplace, our team is already learning about end-users who have had great success integrating these pins on job sites ranging from commercial buildings to newly constructed sport stadiums. Coming this fall 2020, end-users will also find the release of 1/2” aluminum guide top hat pins for steel applications.

MAX USA CORP. is headquartered in Plainview, NY, and is owned by MAX CO., LTD. which is headquartered in Tokyo, Japan. MAX has been recognized as a market leader in the quality manufacturing of tools for over 75 years. MAX has several divisions employing more than 2,000 people worldwide, including 200 R&D engineers.