Jon Schreibfeder, STAFDA Inventory Consultant: Planned Excess Inventory

Manage minimum order requirements more efficiently.

|

|

I received an e-mail from a client yesterday questioning some of the minimum and maximum replenishment parameters we had calculated for his inventory. He said, “You calculated a minimum of 100 pieces and a maximum of 300 pieces for this item. But my vendor will only sell me a package of 1,000. Shouldn’t the maximum be 1,000?”

I called the client and first confirmed that if he could order any quantity he wanted that the calculated minimum and maximum quantities of 100 and 300 would provide good product availability for his customers at a reasonable cost. I then explained that if we raised the maximum to 1,000 pieces, we would be masking a problem referred to as “planned excess inventory.”

The item we were discussing has a replacement cost of $5.30 per piece. If any quantity of the product could be ordered the maximum stock value of the product would be $1,590 (300 piece maximum quantity * $5.30 per piece). However, the vendor requires that a full package of 1,000 pieces be ordered. That means that when the net available quantity of the product drops to 100 pieces a buyer must issue a purchase order of 1,000 pieces.

When the replenishment shipment arrives, we might have as much as 1,100 pieces in stock (the minimum of 100 pieces plus the box quantity of 1,000 pieces). The maximum stock value of the product would not be $1,590, but $5,830 (1,100 pieces * $5.30); a difference of $4,240!

There is a big difference between a buyer making a bad buying decision because he “thought the item would sell” and being forced to buy unneeded stock. |

Most computer systems’ purchase order generation programs will round the quantity needed to reach a maximum stock level to the nearest multiple of the vendor package quantity. For example, if 200 pieces are needed to bring the net available quantity up to the maximum quantity and there is a minimum purchase of 1,000 pieces, a suggested purchase order will be issued for 1,000 pieces.

Setting the maximum quantity to the vendor’s required purchased prevents you from identifying situations where you have to buy more than you want to. We call this unwanted inventory that you are forced to buy “planned excess.”

Why planned excess? Because you didn’t willingly buy it. There is a big difference between a buyer making a bad buying decision because he “thought the item would sell” and being forced to buy unneeded stock. It is a good idea to calculate the planned excess value for each stocked item where your supplier requires you to purchase a certain quantity. The formula to calculate planned excess is dependent on the parameters you use to replenish the product:

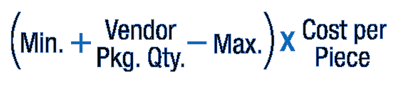

Minimum/Maximum Parameters: If you reorder a product when the net available quantity is less than a minimum quantity and want to buy enough to bring the net available quantity up to a maximum stock level, planned excess is calculated with the formula:

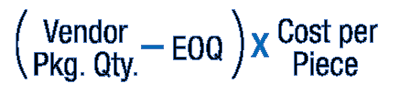

Economic Order Quantity (EOQ): If you reorder items with an economic order quantity (designed to provide the lowest total cost of inventory to your company), planned excess is calculated with the formula:

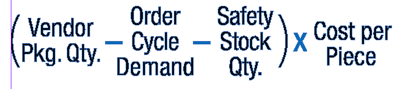

Distribution Requirements Planning (DRP): If your replenishment philosophy is to order just enough inventory to meet customer demand between anticipate stock receipts (also known as an “order” or “review” cycle) plus some insurance inventory or “safety stock” (to protect against stockouts due to unusual demand or delays in receiving a replenishment shipment), planned excess is calculated with this formula:

It is “best practice” to sort all products with planned excess in each warehouse in descending order based on the planned excess value. Starting at the top with the item that has the highest planned excess value ask these important questions:

- Does this item really need to be stocked in this warehouse?

- Can the product be special ordered or transferred from another warehouse as neededto fulfill customer requests?

- Can we you provide your customers with an equivalent but more popular product and avoid maintaining the product in stock?

- Is it practical for two or more branches to split a vendor package quantity when replenishing stock?

- Is there an alternate source of supply that does not require the purchase of a full vendor package? Even if you have to pay more per piece, carrying less stock (with a lower inventory carrying cost) may result in higher overall profits for the item.

In today’s “challenging” economic environment it is crucial that you do not purposely

overstock an item. Identifying items in which you have a substantial value of planned excess leads to maximizing the productivity and profitability of every dollar of your total inventory investment. CS

Jon Schreibfeder is president of Effective Inventory Management, Inc. He has authored numerous articles and several books on inventory management best practices and is the designated inventory management consultant for STAFDA. Jon can be reached at 972-304-3325 or by e-mail at info@effectiveinventory.com