Wright Offers Innovative Wright Grip 2.0 Wrench Design

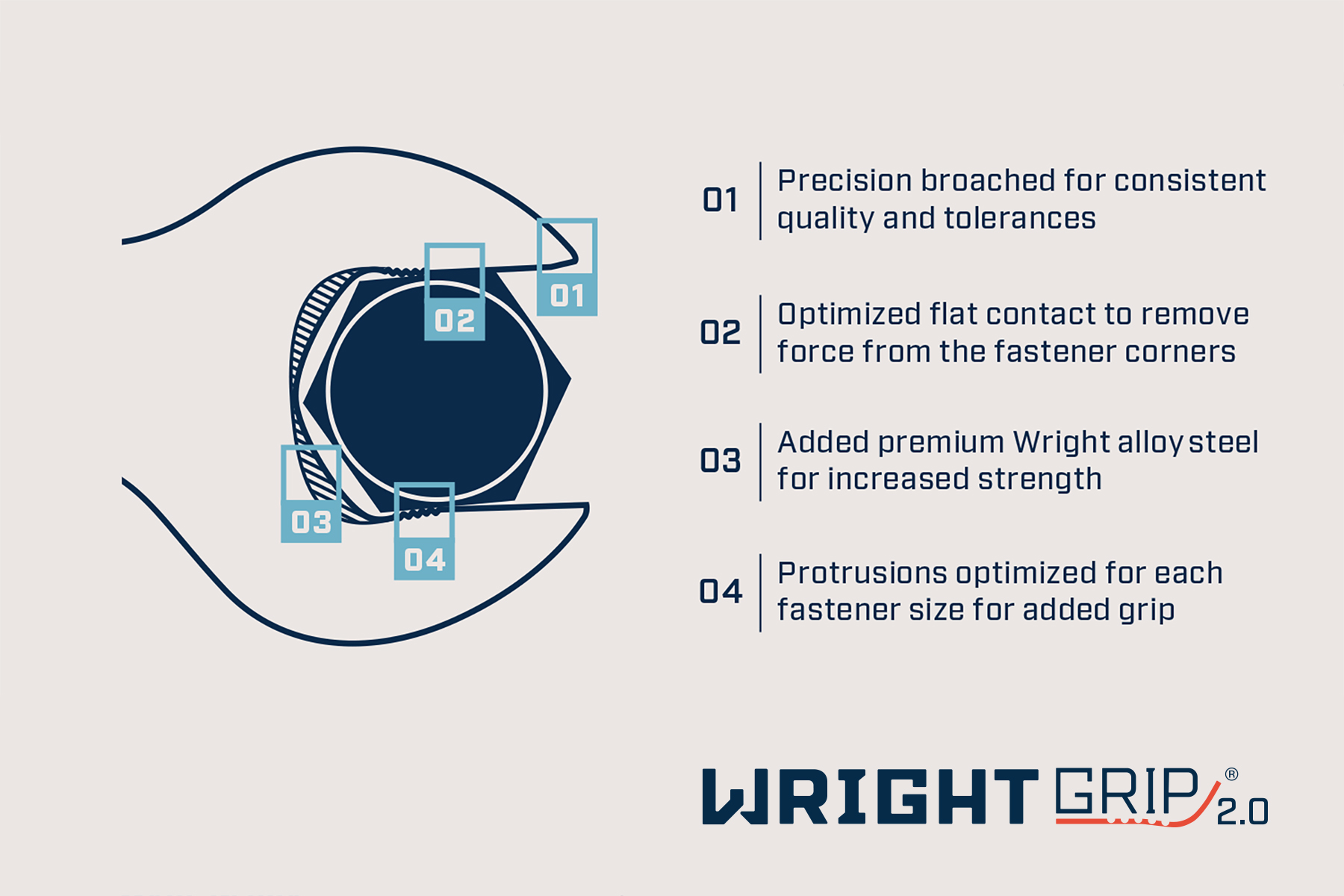

Wright offers innovative Wright Grip 2.0 wrench design (Patent # 11,219,985) that has more steel-to-fastener contact in high-stress areas to stiffen the jaws, increase tool strength and reduce permanent jaw spread. The new design keeps the wrench from slipping to ensure the user’s safety.

Wright Grip 2.0 provides more torque with less fastener damage, distributing stress evenly over a larger contact area and away from the fastener corners. The design incorporates a series of strategically placed teeth or grooves on the insides of the wrench’s two jaws. These teeth allow for a better seating of the wrench on a fastener. One fastener corner locks into the groove so the fastener won’t slip or twist out of the wrench under load.

“We’ve optimized the flat contact areas to remove force from the fastener corners, as well as optimized the protrusions for each fastener size to add grip to your wrenches, which is 50 percent more protrusion engagement than other wrenches,” said Tom Futey, president and co-owner, Wright. “The patented Wright Grip® 2.0 provides the technology to give users a superior anti-slip combination wrench that is perfect for any jobsite.”

Wright Grip 2.0 is constructed with added premium Wright alloy steel for increased strength and precision broaching for consistent quality and tolerances. Precision-placed protrusions are custom engineered for each wrench size to keep it seated on the fastener, increase torque and reduce slippage.

For more information on the Wright Grip 2.0, visit: https://www.wrighttool.com/innovation/wright-grip