Monitoring A/R Vital Signs

Part 2: Systems problems and change.

By asking a series of questions and analyzing results, business managers can identify what’s going right – and wrong.

By asking a series of questions and analyzing results, business managers can identify what’s going right – and wrong.

Part one of this article ran in the December 2009/January 2010 issue of Contractor Supply. Click here to read it.

Part one of this article ran in the December 2009/January 2010 issue of Contractor Supply. Click here to read it.

Systems Problems

On average, 25 percent of the total cost of doing business is tied to inefficiencies and unnecessary friction – the waste of time, energy or materials. Many CEOs will tell you that 25 percent is on the low end.

It’s not uncommon for A/R departments to help manage 90 percent or more of all sales. And in the course of approving credit sales and then managing the resulting A/R, the credit team interfaces with many of the different facets of the supply chain and can identify areas of opportunity for improvement.

The process of pinpointing where something has gone wrong should lead to constant improvement and to new levels of efficiency, which in turn drive down the costs of doing business for seller and buyer alike. Smart business customers understand that the total cost of doing business with a supplier is more important than price.

Nobel Prize winning economist Ronald Coase says that friction/costs are inherent in the process of conducting business. There is the original friction or cost of finding suppliers, employees and customers. There’s the ongoing friction or transactional costs, and then there’s the greatest friction of all, the friction of failure.

Dr. William Edwards Deming, the quality guru, said that the true cost of errors is unknown and unknowable. You can figure what it costs to fix something that’s wrong, but you will never know the effect on your existing customers and on potential future customers.

Prior to entering the speaking and training field in 1982, I had a job as the corporate credit manager for a regional distribution company based in Denver. My duties as the credit manager included the approval of new credit customers and the management of A/R, both current and past due.

I soon found that on average 70-plus percent of all past-due customers had not paid on time due to “something going wrong somewhere.” In the process of fixing things that had gone wrong, I found that I could identify areas of opportunity for improvement throughout the entire supply chain, thus driving down everyone’s cost of doing business.

A vital sign that should be monitored and given management attention and energy is the number of “systems problems” (something went wrong somewhere) and the dollars therein involved. Systems problems are friction and drive up everyone’s cost of doing business, seller and buyer alike.

Change Required

Karl Popper, the well-known philosopher of science, once said, “Our knowledge can only be finite; our ignorance must necessarily be infinite.” To save time by not having to think about everything we do, we learn automatic responses to given situations. Psychologists refer to these learned programs as “fixed-reaction patterns.”

It may not be true of your company, but sometimes employees and business managers operate like automatons. They repeat how they do things over and over again until it becomes ingrained, and as with any habit, thinking is no longer required. All too often, business owners, CEOs and top managers are complicit if not directly responsible.

Our reaction to and behavior in certain situations is the same each and every time. All it takes for this learned “program” to run is the right trigger.

I once saw a business consultant, a small man physically, sit next to his most valuable client. He made himself even smaller by dropping his shoulders and leaning in toward the customer. The client reached over and gave this man a hug. A quick, one-arm, manly hug, but nevertheless a hug. There wasn’t any thinking on the part of the client, just a response to a trigger. Women want to take care of this man because he comes across as being pathetic. The man is good at what he does, but he’s learned how to trigger a protective response from people.

We all have learned programs that kick in without our thinking about it. The busier our lives, the more programs we learn and run. And if we run learned programs all the time, do we forget how to think?

Before change for the better can take place, there must be an acceptance or acknowledgment that a business doesn’t have to be sick in order to get better — that there is always room for improvement.

If you are a business manager, pull out your job description. If you’re a business owner or CEO, pull out your managers’ job descriptions and check to see if they say anything about “constant improvement.” A business manager not focused on improvement becomes an administrator, at best, and a bureaucrat at worst.

Marvin Minsky, author of The Society of Mind, writes that the human brain is a collection of learned “agents,” none of which on their own define the mind, but collectively they are the mind. Companies are like that; they are a collective, and no one person defines the whole. Mahatma Gandhi said that the best way to teach is by example – that you must live the example, and that in living the example, you become the example.

Ask yourself why the Credit and A/R management function exists. How can a business best use its credit and A/R area to its fullest profit potential? And what are the vital signs for monitoring progress?

I’m not a mechanical type, but I’ve learned the hard and expensive way that when the oil or a service engine “idiot light” comes on, it means that you’re an idiot if you don’t pay attention to it. Smart guys pay for their education once; not-so-smart guys buy new engines. CS

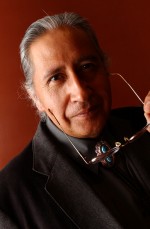

Abe WalkingBear is an International speaker/trainer/consultant on cash flow, sales enhancement and business knowledge organization. Co-founder of www.profitinnercircle.com, and president of www.abewalkingbear.com, he is the author of Profit Centered Credit and Collections, 1999, co-author of STAFDA’s Foundations of a Business, 2007, and co-author of The Best Kept Profit Secret: The Executive’s Guide to Transforming a Cost Center, 2009. Reach him at 719-276-0595; abe@abewalkingbear.com; www.abewalkingbear.com.