Exclusive: Gemtex Abrasives reviews the abrasives market

Gemtex VP Frank Prenda discusses the latest trends and products in the abrasives market.

"The abrasives market continues to be driven by the demand for flap discs and flap wheels which meet the needs of various quality and price levels based on the requirements put forth by the end user," says Frank Prenda, Gemtex vice president of sales and marketing.

"The abrasives market continues to be driven by the demand for flap discs and flap wheels which meet the needs of various quality and price levels based on the requirements put forth by the end user," says Frank Prenda, Gemtex vice president of sales and marketing.

"Many factors, such as working environment, operator skill level, available tools, application and metal types play a vital role in determining the proper disc to recommend for a particular project. Some end users require the highest quality product available due to a pre-established finish or specification requirement.

"Conversely, other customer’s needs are satisfied with products that achieve the grinding objectives set forth, while meeting a determined price threshold. It is the job of the abrasive salesperson to recognize the end user’s key requirements and to recommend products that meet their demands while offering multiple grade and mounting options with their flap disc line," he adds.

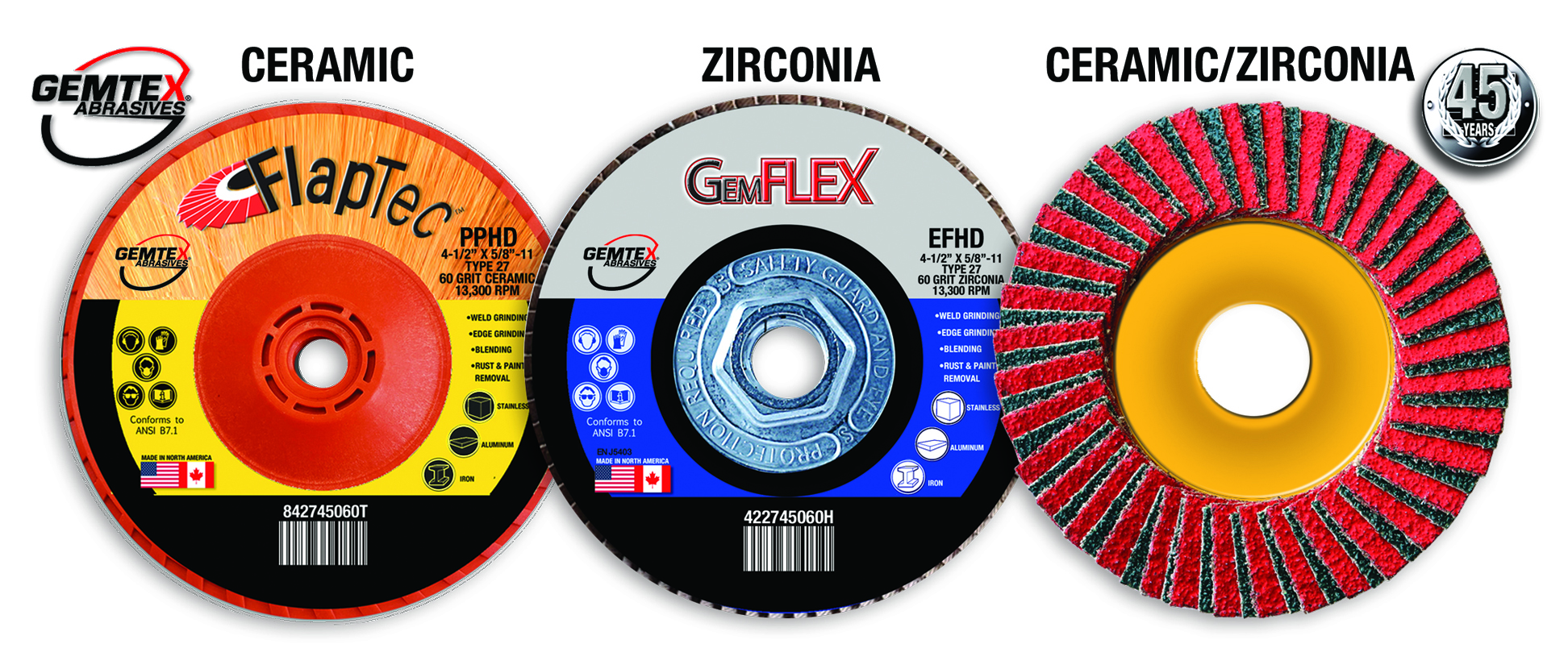

"To meet these demands, Gemtex Abrasives has introduced a New Generation flap disc offering to address both ends of the quality and price spectrum. The new product line, manufactured in our Toronto, Canada factory, is comprised of two brands designated by price and quality.

"To meet these demands, Gemtex Abrasives has introduced a New Generation flap disc offering to address both ends of the quality and price spectrum. The new product line, manufactured in our Toronto, Canada factory, is comprised of two brands designated by price and quality.

The Flaptec line is manufactured with premium zirconia and ceramic cloth available in fiberglass or plastic trimmable backing. The line also includes a ceramic/zirconia alternating flap design which provides a quality level that fits between our 100% zirconia and 100% ceramic flap disc."

"The Gemflex line is an economy zirconia offering which meets the needs of the price conscious customer while providing high levels of productivity and various mounting options. Like Flaptec, the Gemflex line is available with fiberglass or plastic trimmable backing which includes a 5/8”-11 “built in thread”. The trimmable plastic backing allows users to realize longer disc life which further enhances their cost savings. In the abrasives industry, there is no such thing as 'one size fits all'. As manufacturers, we face the delicate balance of aiming to provide quality products which perform efficiently for the demands of market segment 'X' while addressing a different set of requirements for market segment 'Y'."

For more information on Gemtex products, please visit www.gemtexabrasives.com.