|

The trade-off in concrete cutting has always been choosing between speed or blade life. Fortunately, the latest generation of diamond blades for concrete, tile and stone cutting are growing in versatility, speed and ease of use. Today’s blade manufacturers are raising the bar in the pursuit of fast cutting, long-lasting products. These manufacturers are continually innovating new and better designs to make cutting and coring faster, easier and more cost effective for professionals.

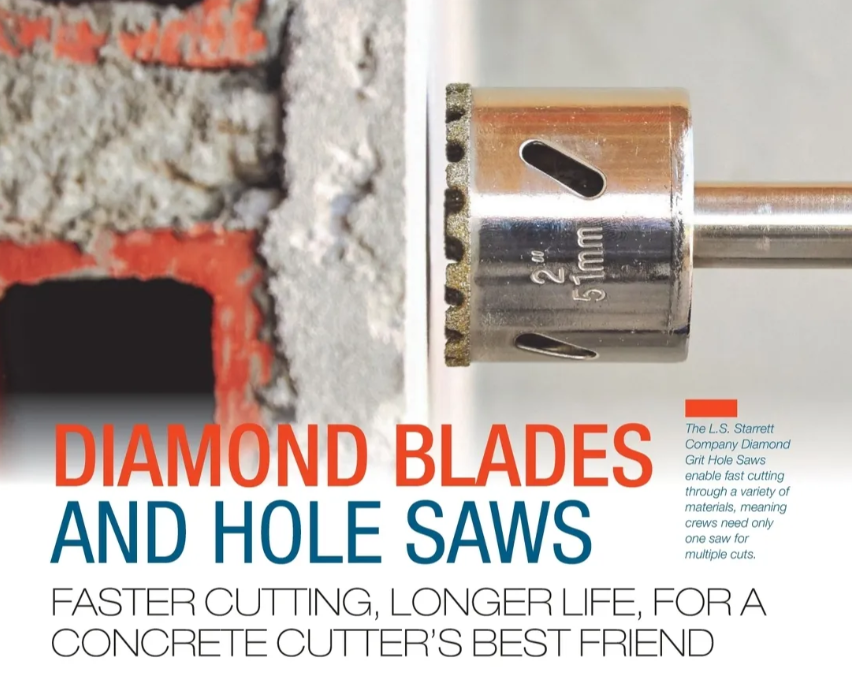

THE L.S. STARRETT COMPANY

From the perspective of The L.S. Starrett Company, the outlook for the construction and distribution industries in 2025 remains optimistic, driven by strong infrastructure investments, residential construction growth and renewable energy projects.

“The adoption of smart technologies and advanced materials, including high-performance diamond tools and cutting instruments, will play a pivotal role in the construction trades,” said Charlie Starrett, product manager, saws and hand tools at The L.S. Starrett Company. “While labor shortages and global uncertainty may persist, we expect moderate growth despite macroeconomic factors.”

The demand for new and innovative solutions that improve efficiencies is a constant as contractors face a continuous labor shortage. In addition, an increase in the number of residential projects is expected to drive further demand for a full range of diamond tools and cutting instruments.

“At Starrett, we understand that it is imperative to lower sawing operation costs to boost productivity,” Starrett said. “That’s why we have designed a high quality, multi-purpose diamond hole saw that has the longevity and high cutting performance demanded in a variety of masonry related materials including porcelain, ceramics, brick and stone.”

He noted that the adoption of renewable energy projects and green building materials will require cutting tools designed specifically for nonmetallic mediums. The anticipation is that there will be a surge in demand for diamond tools in coming years.

Product design changes will play a key role in enhancing tool durability and cutting performance. For example, he said The L.S. Starrett Company has been able to effectively address efficient cutting of both porcelain tile/stone and masonry, with just one hole saw.

“This has been accomplished by using the highest quality industrial diamond, as well as implementing a saw teeth design enhancement,” Starrett said. The Starrett Diamond Grit Hole saws enable fast cutting, as well as the ability to cut through multiple materials, thus reducing the overhead required to complete jobs by requiring only one saw instead of two.

Also, he noted that with the addition of slots on the hole saw to easily remove the cores from cutting, Starrett Diamond Grit Hole saws reduce the time and effort required to remove the cores. To further decrease the amount of time required to manage sawing equipment, the diamond composition and design of the saw allows for self-sharpening.

“The result is that no time needs to be allocated for re-dressing the diamond,” Starrett said. “Instead, the teeth will stay sharp for the entire life of the saw, resulting in consistently fast cutting.”

Additionally, the design update on the teeth enables more cooling action due to increased air/coolant flow to the points of contacts. Cool cutting increases the lifespan of the saw, as well as improving the quality of cuts on a range of materials including masonry and structural blocks, porcelain tiles, stones and more.

“The L.S. Starrett Company’s continuous commitment to producing superior products allows it to stay at the forefront of product and process innovation for saws and cutting technology solutions,” Starrett said. “We are excited about the opportunities ahead and look forward to contributing to the growth and evolution of the industry, while meeting the evolving needs of our customers and partnering with our strategic distributions partners.”

CHAMPION CUTTING TOOL

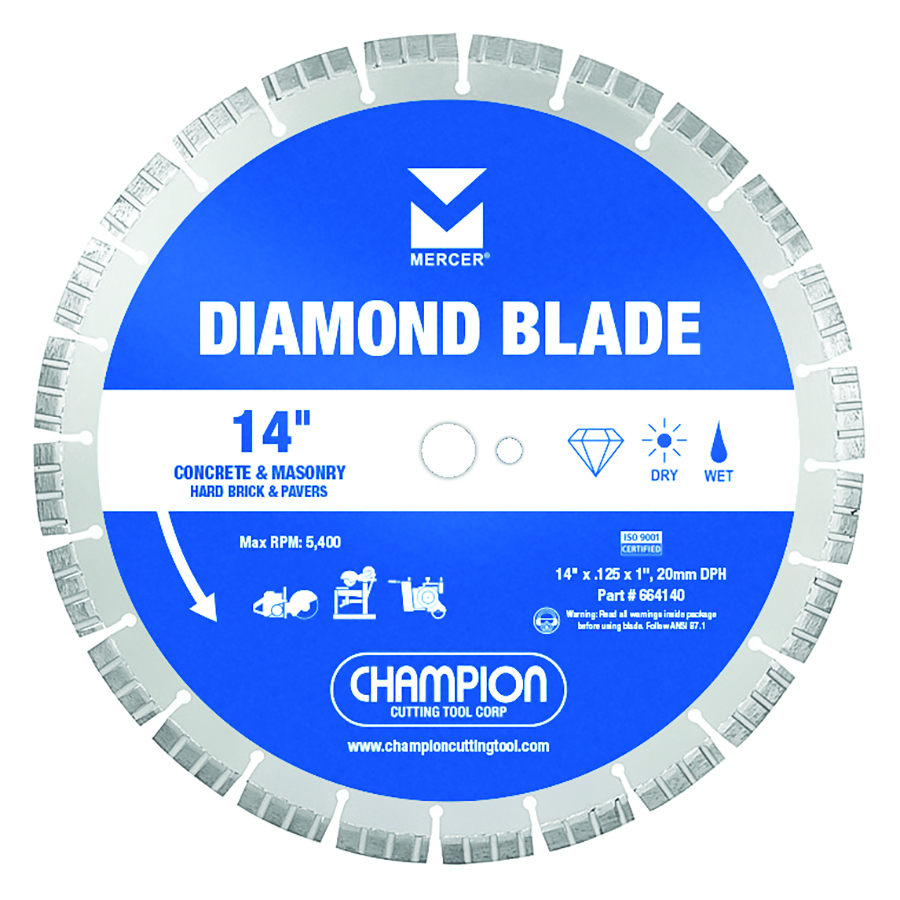

One of the goals for Champion Cutting Tool in 2025 is to educate distributors and users in other markets about its broad offering of high-quality diamond tools.

|

| Champion’s blades have been redesigned for 2025 to include both the Champion Cutting Tool logo and the Mercer sub-brand logo. |

“The difference between metal cutting saw blades and diamond blades is that diamond blades remove material by grinding,” said Allison Frey, chief marketing officer at Champion Cutting Tool. “The type of material and thickness that the user needs to cut determines the type of diamond blade that they use.”

Each Champion diamond blade, which is made of a steel core with diamond segments or a diamond rim, is optimized based on application. They are available in four styles: segmented, turbo, turbo segmented, and continuous rim.

“We can serve users who need to cut concrete, brick, block, stone, and tile with blades from 4 1/2 inches to 14 inches in diameter,” Frey said.

“This will be attractive to users who know the value of Champion tools and give us the opportunity to introduce this category to new customers,” Frey said. “We also focused on creating a functional, easy to read design so that users can easily identify the blade that they need.

LEARN MORE

www.starrett.com

www.championcuttingtool.com

This article originally appeared in the February/March 2025 issue of Contractor Supply magazine. Copyright, 2025 Direct Business Media.