Dynabrade begins sanding pad manufacturing in New York

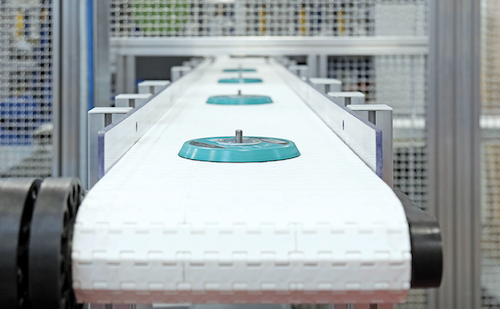

Replacement sanding pads will fit random orbital sanders.

Hardy Hamann, President of Dynabrade, Inc. has announced that his company has begun the process of manufacturing their own line of Random Orbital Sanding Pads at their Clarence, New York facility.

Hardy Hamann, President of Dynabrade, Inc. has announced that his company has begun the process of manufacturing their own line of Random Orbital Sanding Pads at their Clarence, New York facility.

According to Hamann; “We are utilizing state-of-the-art technology to manufacture the highest quality, custom-built and precision engineered random orbital sanding pads in the world.”

Dynabrade’s line of Random Orbital Sanding Pads feature a single piece hub design. This design reduces “face run out” to only .002 - .005, allowing for a smoother running tool, eliminating vibration. Competitor’s hub design are three to four pieces, resulting in additional tool vibration and inefficient sanding.

Available in Vacuum and Non-Vacuum styles, Dynabrade’s line of Sanding Pads is available in various diameters and thicknesses. The pads are also offered in PSA (Pressure Sensitive Adhesive) backing for adhesive backed abrasive discs and hook-face backing for re-attachable abrasive discs. Dynabrade replacement sanding pads fit most competitors’ sanders as well.

According to Dynabrade Product Engineer Mark Lampka; “This will allow our Customers to save money with a highly superior Sanding Pad.”

These products are manufactured in the U.S.A at our factory in Clarence, New York.

Driven by the desire to optimize its customers’ processes, Dynabrade manufactures pneumatic abrasive power tools to offer complete process solutions including industrial vacuums, abrasives and accessories for industrial clients around the world. Learn more at: www.dynabrade.com