|

Classic service is the guiding principle that shaped the founding and continues to influence how the family-owned Industrial Ladder & Supply in Villa Park, Illinois is operated.

President Matt Fuller says classic service means valuing long-term relationships over short-term sales tactics and ensuring that they offer honest recommendations, deliver promptly, stock high-quality equipment, treat customers respectfully and always go above and beyond when called for.

He traces the concept back to the founder of the company, his grandfather, William Fuller Sr.

“My dad (Bob Fuller, past vice president) and uncle (Bill Fuller, past president) always said we offer classic service,” he says. “It’s that white-glove approach, doing whatever we can to provide the customer with what they need.”

For Matt and his cousin, Vice President Brian Fuller, the philosophy is not nostalgic, it’s practical.

After 50 years, the company stands at the intersection of tradition and transformation, where its legacy of classic service meets the modern demands of contractors whose work, equipment, and expectations aren’t slowing down.

|

FOUNDATION IN FAMILY

Industrial Ladder’s beginnings stretch back to 1975, when founder William Fuller Sr. And his wife Gerry incorporated a small, family-owned and operated ladder shop in the Chicago suburbs.

William had gained firsthand experience in the industry working for a wood-ladder manufacturer in New York and later Patent Scaffolding Co.

Recognizing William’s expertise, he was transferred to Chicago to establish a ladder branch within the Patent Scaffolding footprint.

Building relationships, he learned how to run a tight, service-driven operation that would lay the foundation for Industrial Ladder & Supply.

His experiences formed the outline for the enterprise he would eventually build with his family.

Industrial Ladder & Supply began with William, Gerry and their son Bill.

Family members say it was Gerry who was truly the backbone of those early years, handling not only all the accounting and HR but really pouring her heart into every aspect of the business.

“Her dedication, steady hand, and faith in what they were building helped shape the company’s values and spirit,” Matt says.

Bill, retired company president, joined right out of high school and dove into day-to-day work, while Bob Fuller, retired vice president, initially split time between his coursework at Northern Illinois University and part-time responsibilities at the still-young business.

“The company was small, still in its infancy,” Bob recalls. “It was just Bill, mom, and dad, and maybe a part-timer here or there. There wasn’t substantial revenue yet. Bill kind of knew he was putting all his eggs in the basket, but I wasn’t quite there yet.”

As the customer base expanded, so did the need for more hands, and by the early 1980s, both brothers were fully invested in the company.

Even then, the foundation of Industrial Ladder was unmistakably family-driven. Employees became long-term members of the team, some staying for decades, even as the next generation of Fullers grew up around the business.

“It was always about family,” says Brian Fuller, Bill’s son and the current vice president.

Brian recalls traveling with his dad to various branches at age 13, counting inventory and eventually helping train employees on the new computer systems.

Bill’s wife, Carol, took over for Gerry in 1988, carrying the same passion forward that Gerry had.

Devoting countless hours to the business, managing the finances, supporting the team, and keeping everything running smoothly, Carol is credited with leading with kindness and strength.

“She had an incredible work ethic and cared deeply about every person who walked through our doors,” says Brittany Fuller, Matt’s wife and current human resources and marketing director. “Carol’s contributions weren’t just behind the scenes; she helped shape the culture of who we are as a company.”

She considers it an honor to continue the legacy.

“It’s humbling to be part of a family where the Fuller women have always led with dedication, compassion, and pride, standing shoulder to shoulder with their husbands to help the business thrive,” Brittany says.

|

| Industrial Ladder & Supply has always been about family. Pictured here are brothers Bill and Bob Fuller, who were there when it began in 1975. |

COLD CALLS AND FLYERS

In its earliest years, Industrial Ladder grew the hard way: door-to-door sales calls.

“For the first three years, sales were made entirely through cold calls,” Bill says. The approach provided steady business, but the company needed a breakthrough to scale.

The breakthrough came in the form of a 36-page printed catalog, a newspaper-style flyer featuring ladders, scaffolding, van equipment, and pricing. Industrial Ladder began mailing the flyer to every contractor list it could find, purchasing names from marketing companies and flooding local markets.

What started as a simple promotional tool quickly became an engine for growth. Within the first few years, Industrial Ladder mailed roughly 50,000 flyers every two or three months.

The direct-mail strategy shaped Industrial Ladder’s business model for decades, establishing brand recognition and generating consistent leads.

“The success of the flyer built the company,” Bill says.

Geographic expansion was made possible off the success of the flyer, as the company expanded its reach.

As digital technology reshaped contractors’ buying habits, Industrial Ladder & Supply became an early adopter of the technology with its website before online purchasing became the standard.

“We were really in the forefront of developing our website presence and appealing to our customer base,” Bill says. “That became almost a national thing as we would get orders from all over the country as well as from within our local markets.”

Today, as marketing director, Brittany oversees a growing mix of digital outreach tools such as email campaigns and other branch-level online initiatives.

She maintains a centralized Facebook presence while empowering branches to use Facebook Marketplace to reach local contractors directly.

It is, as she puts it, a modern twist on the company’s original philosophy of reaching customers where they already are.

TWO FOR ONE

A major factor in the company’s ongoing success is its dual business structure: construction equipment supply paired with commercial truck and van upfitting.

When construction-supply demand slows in winter, vehicle upfitting often accelerates as contractors purchase and prepare new fleet vehicles for the year ahead.

Brian describes the pattern as a manageable roller coaster in which one side often offsets the other.

Together, the divisions strengthen the company’s value proposition. Contractors can buy ladders, scaffolding, siding tools, and fall-protection equipment while also outfitting the vehicle that will transport those tools to the job.

“It’s something that sets us apart because there aren’t many companies that do it all,” Matt says. “There’s a synergy between a contractor needing equipment, but then also having a vehicle with the means to transport it.”

The hybrid approach dates to the 1980s, when the company began offering ladder racks as one of its first accessories.

“When a contractor buys a ladder, they’ve got to be able to haul it away somehow, so it was a natural extension of the business,” Bob says.

As contractor needs evolved, Industrial Ladder & Supply partnered with brands such as Weather Guard, Prime Design, Adrian Steel, and Knaack to offer different packages.

Today commercial vehicle upfitting packages commonly range from $6,000 to $8,000 per vehicle.

“It’s become a big part of our business,” Bob says.

The company installs all the equipment in-house, working closely with the dealerships and end users to ensure vehicles are delivered ready to work.

It is predominantly custom work. Some customers need a quick turnaround because they’re replacing a damaged vehicle. Others plan fleet builds months in advance.

“For the most part, the end users are going to a dealership,” Brian says. “We have a relationship with the dealership, but we also have a relationship with the end user, so the three of us are working together to get this vehicle outfitted and ready for them.”

On the equipment supply side, Industrial Ladder stocks thousands of SKUs across ladders, scaffolding, siding tools, roofing equipment, fall protection, material handling devices, pump jacks, laddervators, and more.

As a master distributor for more than 25 manufacturers, Industrial Ladder frequently supplies smaller distributors that lack the warehouse space to carry large or infrequently sold items.

“You can find a six-foot step ladder anywhere, but you can’t find a 40- foot extension ladder everywhere,” Brian says. “A lot of the smaller supply houses might want to devote one section of pallet racking to six- and eight-foot ladders, but they want to be able to still assist their customers, so they’ll call us.”

Replacement parts also generate consistent business.

“Most of our equipment is repaired by the customer because of the expense of buying a new one,” Brian says.

To further diversify revenue, Industrial Ladder has introduced rental programs at some branches, offering pump jacks, siding brakes, and ladders for short-term use.

CUSTOMERS LARGE AND SMALL

Industrial Ladder’s customer base is unusually broad, encompassing commercial contractors, roofers, electricians, HVAC technicians, pestcontrol companies, smaller distributors, dealerships, leasing companies like Enterprise, and major utilities such as Baltimore Gas and Electric.

“We don’t turn away any business,” Brian says.

Loyalty to the company extends across generations, for both the contractor and at Industrial Ladder.

Customers frequently tell Matt they purchased a siding brake or extension ladder from his father years ago and have returned because of the service they received at the time.

To maintain that loyalty, he says it is important to be able to meet the needs of the customers quickly.

Matt says this involves having a deep inventory of quality products and providing delivery within a reasonable 200-mile radius of each branch.

Even within that radius, it is challenging, as many customers have that Amazon mindset of that next-day delivery, which is not always feasible.

“We stock our warehouses with our major brands because if we don’t have it, they will be going to one of our competitors,” Matt says.

When possible, LTL shipments are avoided to help prevent potential damages.

“We try to do as much of it on our own vehicles as possible, because we know the customer is going to get a quality product and it will arrive without any damage,” Brian says.

While Industrial Ladder does not have a central distribution hub, the Villa Park site unofficially serves as one.

For high-value or high-volume items, the company brings more product into Villa Park, loads mixed shipments onto trucks, and distributes them to its branches as needed.

This centralization allows for better bulk pricing, with the savings ultimately being passed on to customers.

CULTURE OF TRUST

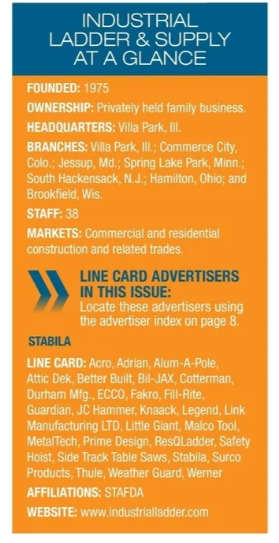

Industrial Ladder & Supply operates seven branches in seven states.

Each branch functions as a semi-autonomous unit, reflecting the culture of trust and accountability that the Fuller family has fostered over the decades.

Some branch managers prefer to stay inside the building, managing operations, inventory, and customer service. Others thrive out in the field, selling face to face. The company doesn’t impose a one-size-fits-all model.

“We try to let them run their branch as if it’s their own,” Brian says.

Branch size varies but each location includes a showroom, warehouse and office space. Minimum staff includes a branch manager, installer and driver, with additional support added as volume increases.

In total, the company has about 38 employees and operates 18 delivery trucks.

Matt and Brian prioritize communication and make annual visits to each location, making every effort to not micromanage the efforts at specific locations. In addition, branch managers meet once or twice a year, sharing insights, challenges, and best practices.

“It’s just really making people feel like we’re a family, so if you’re hired, you’re our family now,” Brittany says. “We want to deliver like our business does; you are part of our family now and keeping that culture really positive is important.”

Being team-oriented, she says it is important to maintain that good workplace culture, because while operating autonomously, all seven branches should still feel unified.

“We’re a very close knit, family-owned business and we pride ourselves on that classic service that all revolves around hiring a good team to help you provide that,” Brittany says.

At the branch level, to further local connections, she says more efforts are being made to join industry associations and get the company name out to the right people.

“We’re constantly trying to tap into what is appropriate and what seems to work best and resonate more with our business,” Brittany says.

|

THE NEXT RUNG

As Industrial Ladder looks to the future, Matt says the company is focused on expanding its vehicle-upfitting capabilities, strengthening digital tools, exploring new geographic opportunities, and developing employees who uphold the company’s service-first values.

“We don’t just open a branch to scale up,” Matt says. “We do it because there is an opportunity in that market that we learn about from our suppliers.”

The Denver branch, opened in 2025, marked the first expansion under Matt and Brian’s leadership. Matt emphasizes that future expansion is not entirely focused on new branches.

“What we’re really trying to do now as a company is train all our branches to be really specialized in the truck and van upfitting,” he says. “There are a lot of opportunities there.”

As it continues to move up the ladder of success under the current generation of leadership, Industrial Ladder & Supply maintains its core values it’s had since 1975.

“We pride ourselves on carrying the best,” Matt emphasizes. “We don’t just push the economical option; we push what we believe is a quality product.”

This article originally appeared in the December 2025/January 2026 issue of Contractor Supply magazine. Copyright, 2025 Direct Business Media.