New TPO With Seam Protector Offered by MuleHide

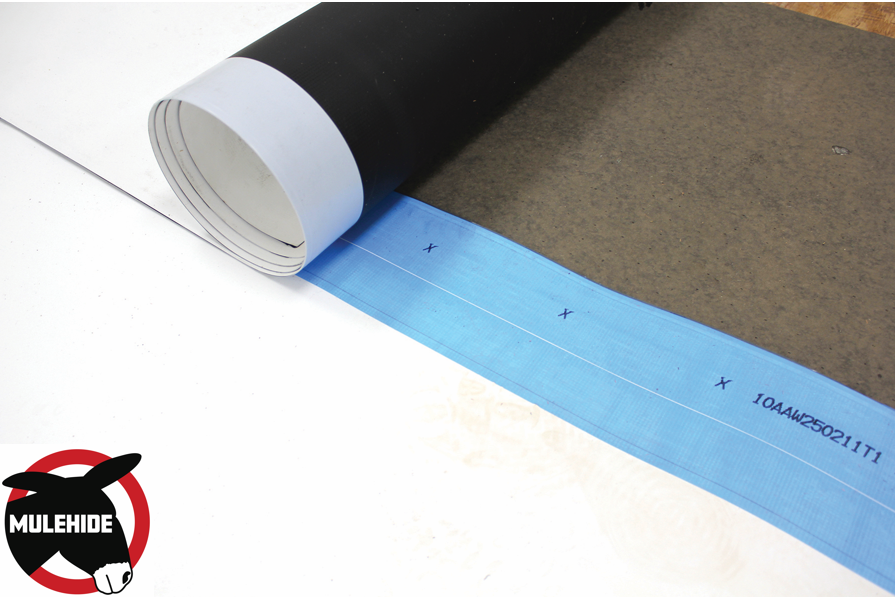

MuleHide has unveiled a new TPO with Seam Protector to help produce higher-quality seams while eliminating the step of cleaning seam areas before welding.

|

The polyester-reinforced Standard TPO membrane, available in 60- and 80-mil thicknesses has a factory-applied film on the top and bottom lap areas. The film shields the seam areas from dirt, debris and bonding adhesive overspray, keeping them clean during the installation process. It is then quickly and easily removed, revealing consistent, ready-to-weld seams with no need to clean them first.

Eliminating the cleaning step boosts crew efficiency. No additional crew members are needed to prevent overspray or keep dirt and debris off the membrane.

According to MuleHide, removing the Seam Protector film is up to 70% faster than cleaning the seam.

The factory-clean seam areas result in better quality, more consistent welds. Weld strength is 10% higher compared to seams that were exposed to dirt. There is also less chance of dirty seam areas resulting in “cold welds” that can lead to leaks, open seams and other performance issues.

TPO with Seam Protector can be used in fully adhered, induction-welded and mechanically attached applications and as flexible membrane flashings for walls, curbs and other details.

Like other MuleHide TPO membranes, it delivers years of hassle-free performance, withstanding sun, hail, rain, snow, heat, cold, building movement, airborne bacteria, algae, mildew and mold.

TPO with Seam Protector membranes are available in white, gray and tan. Rolls are 100 feet long and are available in 10-foot and 12-foot widths.