|

Minimizing Waste and Maximizing ROI on the Jobsite

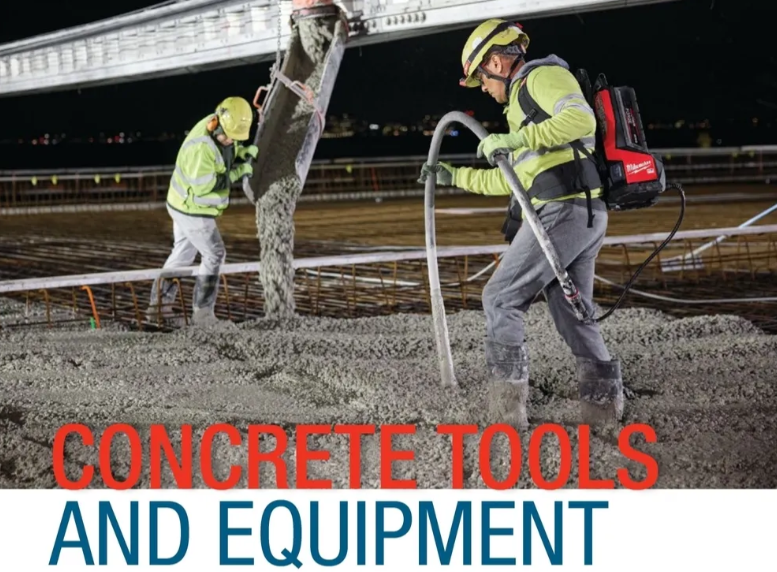

Concrete work remains one of the most demanding areas in the construction industry. Contractors in the trade are poised for challenges and opportunities in 2025 as they navigate ongoing pressures like tight margins, labor shortages, and rising materials costs. On the other hand, the demand for efficient, innovative tools creates new opportunities to improve productivity and profitability on the jobsite. These manufacturers continue to be among the leaders in the field that continue to advance technology to make jobsites more efficient.

MILWAUKEE TOOL

Even in the world of concrete work, more professionals are increasingly adopting the compactness and versatility of battery-powered equipment to adapt and comply with local regulations. Designed to take on the very same gas and corded equipment that the construction industry has depended on, battery-powered tools and equipment address common hazards and frustrations.

“Milwaukee Tool understands it takes to combine advanced batteries and electronics to deliver disruptive innovation for the jobsite,” said Brandon Fredricks, senior product manager at Milwaukee Tool. “With trends in technological developments and a focus on safety, a growing number of battery-powered equipment solutions are emerging, and even more are expected to appear.”

A key factor leading trade professionals to alternative power sources relates to the hassles of equipment maintenance, gas storage, and refueling. The physical strain of moving heavier equipment and tools also has a significant impact on productivity and efficiency on the jobsite. Fredricks noted that noise, emissions, and the potential trip hazards of corded tools can pose serious safety risks.

Recognition of those frustrations and hazards has supported an increased interest and demand among contractors for more advanced battery technologies including longer-lasting batteries and faster charging capabilities. These innovations will help minimize downtime during charging and maximize uptime on the jobsite.

|

| Milwaukee Tool’s MX Fuel Pipe Threading Machine allows you to work anywhere on a jobsite and is easily transportable with the combined cart. |

“Working alongside professionals in the field, Milwaukee Tool found a need for battery solutions that were highly portable, emissions-free, and increased productivity on a jobsite,” he said. “With quieter operation and compact form factors, users can take power equipment anywhere with them on the job. Be it indoor, outdoor, or remote parts of the site.”

Among the most recent examples are the MX Fuel RedLithium FORGE battery packs, one of the longestlasting and fastest charging options in Milwaukee’s lineup. Fredrick said the built-in REDLINK Intelligence monitors cell voltage, temperature, and charge status to keep the batteries from overheating. In addition, the RedLithium FORGE battery packs include the COOL-CYCLE Active Cooling System, which when paired with a COOL-CYCLE enabled charger, actively cools the batteries, resulting in faster charging and less downtime.

“As the industry evolves, advancements in battery technology will continue to drive efficiency, performance, and sustainability across a wide range of solutions and applications,” Fredricks said. “As a leader in battery-powered technology, we remain committed to advancing our trade-focused solutions that are fully compatible with the MX FUEL System, offering professionals emission-free solutions for a safer working environment.”

IGNITE ATTACHMENTS

“Precision, speed, and uptime are critical, and contractors need tools that help them deliver results efficiently, even under tight timelines,” said Trisha Pearson, business manager for Ignite Attachments.

One of the most significant trends shaping the construction trades and concrete tools industries over the past decade is the push to do more with less. The shift is driven by economic pressures, labor shortages, and the need to stay competitive in a rapidly changing market.

“Contractors are being asked to deliver high-quality results with fewer inputs, fewer pieces of equipment, and often fewer employees,” she said. “Skilled workers are harder to come by, and contractors are feeling the strain of having to complete complex jobs with leaner teams.”

In addition, concrete professionals are also contending with clients demanding faster project completion times, sustainable practices, more cost-effective solutions, and high-quality results, even under tight schedules. This puts pressure on contractors to optimize every aspect of their operations.

That ability to quickly adapt to changing jobsite needs and deliver precision without delays has become essential. The competitive landscape is shifting as contractors who streamline operations, cut down on inputs, and deliver results with fewer resources come out ahead. Ultimately, contractors are looking for ways to minimize waste and maximize ROI.

From small contractors looking for high-ROI solutions to larger operations managing multiple jobsites, there’s a growing need for tools that boost efficiency without sacrificing quality,” Pearson said. “Ignite Attachments is ready to meet that need with tools like our concrete chute bucket and a commitment to delivering the right fit, at the right time, and for the right price.”

|

| Designed with building contractors in mind, Ignite Attachments’ tools take the hassle out of small-scale work and can reduce the need for labor-intensive processes. |

Designed with building contractors in mind, Ignite’s concrete chute attachment takes the hassle out of small-scale concrete placement and reduces the need for labor-intensive processes.

“Whether pouring footings, filling forms, or managing tricky placements, the chute bucket makes it easier to get the job done right,” she said. “For contractors, it’s a time-saver that minimizes waste, contributing to better margins and a more efficient workflow.”

“The future of the construction industry is a mix of high-tech advancements and straightforward, practical tools that get the job done efficiently,” Pearson said. “While automated and connected solutions often grab headlines, there’s a growing recognition that not every task requires complex, expensive technology. Sometimes, the best innovations are the ones that simplify workflows, reduce costs, and deliver reliable performance.”

She said Ignite Attachments believes there will be a continued appreciation for tools and attachments that prioritize functionality, durability, and ROI over bells and whistles.

“Contractors need equipment that performs consistently, stands up to tough conditions, and fits seamlessly into their existing workflows,”

Pearson said. “It’s not just about making tasks easier; it’s about helping contractors do more with less while staying competitive in a fast-paced industry.”

At the same time, she acknowledges that technology will continue to play an important role, particularly for tasks where automation can significantly enhance precision or productivity. However, the more high-tech solutions often come with steeper learning curves and upfront costs that may not be practical for every contractor.

“The sweet spot lies in combining straightforward tools with thoughtfully integrated innovations or solutions that strike the perfect balance between simplicity and performance,” Pearson said.

As a company, Ignite Attachments remains optimistic about the future as the construction industry continues to call for more efficiency from its equipment.

“Contractors are some of the most resourceful professionals out there, and with the right tools in their hands, they’re more than ready to rise to any challenge 2025 may bring,” Pearson said. “Ignite is proud to be part of that journey, offering solutions that help them build better, faster, and smarter.”

Ignite Attachments will be unveiling new products in 2025. Pearson noted that the new tools reflect the company’s mantra of delivering the right fit, at the right time for the right price.

“These new additions to our lineup will take us into new carrier capabilities, broadening the range of machines we support and opening up new opportunities for the contractors we serve,” Pearson said.

“Whether you’re running compact track loaders, skid steers, mini skids, compact tractors, or something else, these new offerings will help you expand your capabilities and take on new challenges, with confidence.”

Details were not available at press time, however, Pearson said the new tools would help contractors get more out of their equipment, tackle tougher jobs, and stay within budget.

“This is just the beginning of what’s shaping up to be a big year for us,” Pearson said. “We’re constantly looking for ways to innovate and provide even greater value to the professionals who rely on our products.”

TORO

In 2025, Toro is anticipating continued growth in the interior construction and demolition sectors, driven by an increasing understanding of the opportunities for electric equipment in these areas.

Like Ignite Attachments, Milwaukee Tool and other manufacturers, Toro is positioning itself as a solution to labor shortages and tight deadlines with its batterypowered equipment.

“Toro is at the forefront of this revolution, providing versatile, zero-engine emission equipment,” said Kaitlyn Ingli, product marketing manager at Toro.

|

|

Building on the ongoing trend toward battery-powered equipment, Toro recently added the eDingo TX 750 and the electric high-lift Ultra Buggy e2500-THL to its e-lineup. |

The company’s line-up of electric construction equipment includes the Toro eDingo 500 and the Ultra Buggy e2500.

The introduction of the machines follows an ongoing trend of contractors opting for batterypowered machinery due to quieter operation and zero emissions which make them ideal for both interior and noise-sensitive environments.

“Labor shortages are prompting the industry to invest in equipment that simplifies operations and reduces repetitive motion injuries, enabling workers to handle complex jobs efficiently and comfortably,” Ingli said, adding that equipment versatility is also essential. Compact utility loaders, such as Toro’s Dingo lineup, can complete several tasks on a jobsite. With a floor scraper attachment to scrape the floor, a bucket can then be attached to clear and haul away the debris.

“Battery-powered equipment can open the door to new, interior job sites and may even help contractors win bids,” Ingli said. “Toro has introduced equipment with all-day runtimes featuring high capacity and performance that doesn’t compromise, helping to overcome outdated stigmas surrounding electric equipment.”

She said the anticipation is that in the longer term, the construction and demolition industries will see widespread adoption of battery technology. Toro remains committed to the concept as it continuously enhances its HyperCell battery technology.

According to Ingli, the eDingo 500 and electric Ultra Buggy e2500 were just the beginning of Toro’s venture into battery-powered equipment.

“We recently launched three new battery-powered offerings that offer contractors, municipalities, landscapers, and homeowners an electric-powered solution for any job site,” she said. Toro recently unveiled the eDingo TX 750 narrow and wide track, the electric high-lift Ultra Buggy e2500-THL, and the electric swivel Ultra Buggy e2500-TS.

Building on the success of the eDingo 500, the new Toro eDingo TX 750 is available in narrow and widetrack models. Ingli said it combines the versatility and maneuverability of Toro’s Dingo line with advanced electric power and a 750-pound rated operating capacity.

Powered by the Toro HyperCell Power System, she said the eDingo TX 750 offers up to eight hours of runtime, ensuring uninterrupted productivity for crews working long shifts. At 31.5 inches, it fits through three-foot doorways and maneuvers easily in confined spaces like hallways, small rooms, and through gates.

Ingli said the new electric Ultra Buggy e2500-THL is a high-lift solution that will revolutionize material handling.

“Engineered to outperform other material handling buggies, the new Ultra Buggy e2500-THL boasts the ability to effortlessly dump into a 30-yard dumpster, navigate tight spaces with precision, and operate continuously for up to eight hours on a single charge,” she said.

With a carrying capacity of 1,250 pounds at full 76-inch dump height and 12.8 cubic feet volume, the Ultra Buggy e2500-THL is ready to take on the most debris-intensive tasks, whether hauling concrete rubble, building materials, or trash.

Also, the electric swivel Ultra Buggy e2500-TS combines the performance of Toro’s swivel Ultra Buggy with battery technology. With 14 cubic feet of carrying capacity, a 2,500-pound load rating, and up to eight-hour runtime, the Ultra Buggy e2500-TS is engineered to handle a wide variety of materials indoors or outdoors.

“Toro is excited to continue to expand its portfolio of battery-powered solutions, focusing on improving jobsite efficiency and productivity,” Ingli said.

JLG

Concrete contractors are always looking for ways to do their work more efficiently and safely.

“This is not a one-size-fits-all industry because concrete projects each have unique needs and requirements based on the jobs that must be performed,” said Craig Edwards, vice president of national accounts at JLG. “Whether working on new construction projects or making additions, alterations, or reconstructions, workers in concrete industry perform physically demanding work."

In addition, the tools and equipment used by concrete workers are an extension of the tools they need to accomplish their specialty work. For example, telehandlers are often used on jobsites to move and lift concrete, and boom lifts and scissor lifts are utilized to help concrete workers access areas at height after the concrete is put in place.

Edwards noted that the demanding work done on the jobsites is taxing on the equipment too, especially those machines used for lifting and moving heavy loads of concrete. Like other manufacturers in the construction industry, JLG’s customers face similar labor challenges.

|

| Concrete projects each have unique needs and requirements and therefore the equipment needs to be equally versatile. |

JLG approaches the issue from two fronts, promoting how useful and safe the work is, while also continuing to innovate new solutions.

“Training is key, and we also know that we need to continue developing innovative solutions that will make construction companies more efficient and increase the sustainability of our equipment,” Edwards said. “In some ways, you can handle the tight labor market through technology that improves efficiencies, but you can’t eliminate the need for more people in the trades.”

In addition to the labor market, JLG COO Tim Morris noted more of the company’s customers are facing the challenge of being asked to utilize more environmentally friendly equipment or conduct their business in a sustainable fashion.

“The world needs cleaner, more efficient products,” Morris said. “As an OEM, we want our machines to be cleaner, however, they still have to maintain the same efficiency level or become more efficient moving forward while satisfying those important environmental factors today.”

He noted that contractors buying JLG products are sophisticated, have sustainability targets and goals, and are expected to adhere to certain standards.

“They want us to produce cleaner and greener products,” Morris said.

|

| JLG telehandlers can revolutionize concrete operations, being a go-to tool for lifting and moving heavy concrete loads with precision. |

In addition, the COO pointed out that moving forward, JLG is working on machines with more automation for unmanned applications.

“We’ve experimented with technology a lot, and it’s going to attack some of the labor issues in the industry,” he said. “We’re also producing machines that will get smarter and diagnose themselves if there’s an issue. We want to know about problems before they manifest themselves.”

For JLG, electrification and connectivity are key.

“The whole world is connected, and it is about time that the construction and access industries embrace that fully,” said Rogerio dos Santos, vice president EMEAI region and global strategy.

He said JLG is heavily investing in it, constantly assessing and matching the current state of technology in electrification and alternate fuels.

“We are also examining where our customers want to take new technologies and where our products are so we’re ready to go,” dos Santos said.

Currently, technologies in which machines can sense their environment and jobsite conditions are being developed. In addition, each machine is part of a customer’s fleet on the jobsite, which can be tracked via their smartphone or other portals.

No matter the innovations, jobsite safety remains an ongoing focal area for contractors, especially in applications where crews must work at height or perform heavy, repetitive tasks. There is no question that the safest place for an operator is on the ground.

With today’s advanced technology, many access OEMs can help keep operators on the ground with robotics and autonomy, making it possible for workers to control or monitor a machine at a safe distance on an autonomous or semi-autonomous basis.

Reducing the physical and safety barriers can lower the overall hazards associated with construction jobs. As a result, dos Santos said many construction equipment manufacturers are searching for ways to boost equipment safety and efficiency by using automated solutions.

“The biggest driver in advancing autonomy and robotics in access equipment is the constant need to improve productivity, streamline repetitive processes, and reduce operating costs,” he said. “Robotic technology can handle repetitive tasks faster and at a more consistent level of quality.”

The shift in operation benefits current workers by making their jobs more manageable, and efficient and has the potential to attract a new, diverse workforce.

“People who previously viewed construction as too physically demanding or hazardous might now see it as a viable and appealing career option,” dos Santos said.

At JLG, adopting new technologies like autonomous machines and robotic solutions is nothing new. He said such technology will be crucial in reshaping the landscape of construction work, making it even safer and more inclusive for everyone involved.

“In our work with Construction Robotics we have supplied two machines for integration with CR’s new battery-powered compact MZ100 Material Unit Lift Enhancer (MULE), a JLG RT3394 scissor lift and a Hinowa TPX4000 tracked pallet jack,” dos Santos said. “This initiative aims to use robotics on machines commonly used by masonry and concrete contractors to lift and place concrete blocks.” Typically, such cumbersome, repetitive construction tasks often result in cumulative injuries.

He said JLG continues its collaborations with Construction Robotics to refine the products further. The company has launched an adapter that integrates with the CR MZ100 MULE with a JLG RT3394 scissor lift, which provides both operation at adjustable heights and mobility to the robotic arms.

“By doing so, we strive to provide our customers with solutions that elevate safety and efficiency standards in the construction industry,” dos Santos said.

LEARN MORE

www.igniteattachments.com

www.toro.com

www.milwaukeetool.com

www.jlg.com

This article originally appeared in the February/March 2025 issue of Contractor Supply magazine. Copyright, 2025 Direct Business Media.