|

Bulk and collated fasteners characterized by the assembly of fasteners into strips or collated forms for efficient and automated applications, represent a crucial segment of the broader fastening industry.

The market outlook for collated fasteners inevitably depends on the broader view of the construction industry, which faces a range of challenges in 2025.

Manufacturers such as Simpson Strong-Tie, Kyocera SENCO Industrial Tools, Pneu-Fast, BECK America, and Malco Tools are cautiously optimistic as current conditions temper growth.

Supply chain disruptions in shipping and manufacturing, worsened by tariff policies, are compelling several companies to reevaluate their sourcing strategies. Labor issues continue within the industry, as contractors rely more on semi-skilled workers.

“We feel that economic unpredictability created by current policies relating to tariffs, inflation, and interest rates will not abate for the foreseeable future,” said Reno Joseph, president of Pneu-Fast. “The unfortunate truth, we believe, is that builder uncertainty due to tariffs will impact future home builds and reduce demand on fasteners and building materials in general through 2025.”

Until interest rates decrease and newly planned United States manufacturing facilities become fully operational, many manufacturers expect to see linear growth in the near term.

“Sadly, the bedrock of our industry may rest upon reconstruction, rather than construction, at least until the homebuilding market rebounds,” Joseph said.

However, outside of the more direct economic conditions, the collated fastener market continues to advance as innovations are brought to improve fastener performance and jobsite productivity.

A significant aspect contributing to the continued growth of the market is the demand for fastening systems designed for heavy-duty applications. Focusing on durability and performance, manufacturers are producing fasteners that can endure more stress, including environmental challenges, while remaining aligned with industry standards and regulations.

BECK AMERICA

With over 120 years of experience in the fastening industry, BECK is a recognized leader.

“While the fastener industry is experiencing slow but steady growth overall, the green building sector is poised for significant expansion,” said Brett McCutcheon, general manager of BECK America and ET&F Fastening Systems. “Increasing awareness of sustainability, coupled with client demands for energy efficiency and the economic advantages of green construction, has made this approach increasingly popular. We anticipate this trend will continue indefinitely.”

In response to the current trends and customer needs, BECK is dedicated to continuous improvement and innovation.

|

| BECK SubLoc Pro collated subfloor screws are specifically designed to grab and hold subfloor to eliminate floor squeaks that are the number one cause of costly callbacks for builders. |

“In the green building sector, we have expanded our Lignoloc family of pneumatically driven wooden nails,” he said. “Our newly launched stepped shaft Lignoloc system provides innovative solutions for sustainable construction across a broader range of applications.”

BECK achieved North American code approval for the use of Lignoloc wooden nails in structural applications in October 2024. In addition, McCutcheon said BECK’s Scrail family of nail screw fasteners is still a key focus for innovation.

“We are committed to enhancing these products to meet our customers’ evolving needs,” he said.

The company recently introduced Scrail Chipboard for temporary applications. He said they are for tightening warped boards while offering excellent driving and retightening performance.

Additionally, BECK’s Scrail Subloc Pro is designed to ensure squeakfree subfloors, which saves contractors money by reducing or eliminating callbacks.

“To address labor shortages, BECK has prioritized expansion and development in automation over the past few years,” McCutcheon said. “By automating repetitive tasks, we can achieve consistent and accurate results, allowing our workforce to focus on higher-priority areas.”

Looking ahead, he said BECK is optimistic about growth and its commitment to innovation.

“We remain steadfast in our dedication to quality and responsiveness to customer needs, ensuring we stay at the forefront of trends shaping the future of the fastening industry,” McCutcheon said.

MALCO GROUP

To be profitable, trade professionals must move quickly on jobs. However, they also must balance that speed with doing the best job possible.

|

| The new black-painted Zip-in Self-Piercing Sheet Metal Screws from Malco Tools are ideal for contractors looking to achieve flawless finish on gutters, downspout sections or other metal projects. |

Director of Product Management Andrew Knutson said the Malco Group, formed in late 2024, addresses contractors’ needs to find high-quality, efficient, and ergonomic solutions in one place.

“As we like to say, everything you need for the back of your van under one roof,” he said.

By bringing a variety of brands and products for HVAC/R and building construction under one umbrella, the Malco Group can provide solution bundles to make trade professionals’ lives easier by streamlining orders through one supplier.

The expanded portfolio includes condensate management (Aspen Pumps, Beckett); HVAC/R maintenance and cleaning chemicals (ACE Chemical, HydroBalance); refrigerant recovery and leak detection (C&D Valve); sheet metal and installation tools (Malco Tools); worksite accessories (Unilite); and support systems and mounting solutions (Big Foot Systems).

“At The Malco Group, we believe that a quality job should extend even to the smallest part of the job and fasteners are no exception,” Knutson said.

The company’s newest highquality fastener offering is a blackpainted version of the patented Zip-in Self-Piercing sheet metal screws, available in a variety of sizes and bulk quantities ranging from 100 to 18,000.

Knutson said the new color option is an ideal solution for building exterior pros looking to achieve a flawless, cohesive finish on gutters, securing downspout sections, fascia, and other sheet metal projects.

Zip-in screws are zinc plated and feature a sharp, tapered point for fast starts and reliable piercing, paired with a single-thread design for holding power in metal-to-metal applications.

PNEU-FAST CO.

Pneu-Fast primarily manufactures collated nails, all made in the U.S. For many years, the company has fostered the idea that “better nails make stronger frame-ups and stronger inner walls” that are far more resistant to hurricane winds, tornadoes, and other destructive weather conditions.

“Since our inception, we’ve developed innovative fasteners that tests prove hold 30% to 50% stronger than any other top brand fasteners on the market,” Joseph said. “Stronger holding power will become the driving force for fasteners able to meet the demands of stricter building codes across the country. “

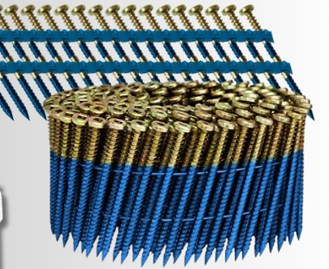

|

|

True-Strike 21-degree plastic-strip nails from Pneu-Fast are American-made with high quality steel for maximum strength. |

As a “Made in the USA” brand, Pneu-Fast is accustomed to competing with cheaper, offshore fastener manufacturers.

“Unfortunately, we don’t think tariffs will level the playing field,” Joseph said. “We’ve always managed to stay competitive, and we’re investing in next-generation automation to improve manufacturing efficiency to deliver even greater value to our customers and narrow any gaps in cost.”

He suggested that while some competitors fear product improvements might send them out of the market, Pneu-Fast has been manufacturing and improving nails for over 30 years.

“We know that the cost for a Pneu-Fast frame-up on a typical newly constructed home is usually $50 or less versus even the cheapest imported nails,” Joseph said. “That’s a small price when you figure in the added warranty expenses incurred to repair sticky windows and doors and squeaky floors resulting from inferior nails.”

As one of the few remaining 100% U.S.-made collated nails, Pneu-Fast’s goal is to win back the market share with American-made quality.

SENCO

On the fastener performance front, SENCO recently announced that it upgraded its 30-degree paper tape nail line to its proprietary ProHead offset full-round head design.

|

| SENCO has transitioned its 30-degree paper tape nails to its proprietary ProHead offset full round head design. |

“We chose to standardize on the ProHead design for our full line of paper tape framing nails because of its strength and versatility,” said Ryan Schuler, product manager at SENCO. “Customers will benefit from the increased holding power and fewer partial drives and pull-outs.”

ProHead is an offset head design that provides increased holding power without compromising efficiency, productivity, or versatility.

Schuler said the ProHead 30-degree paper tape nails feature SENCOTE proprietary coating that provides a dual purpose: acting as a lubricant to ensure more fully completed drives and as an adhesive for one of the highest withdrawal values in the industry.

Traditionally, framers have chosen between clipped-head or full-round head style nails depending on their needs. The clipped head design allows for a neat and compact framing assembly. It also minimizes the space between nails on a collated strip and enables a steeper collation angle. This allows for a greater quantity of nails on a strip and fewer reloads. Full round head nails, on the other hand, are recognized by some building inspectors for their holding power and enhanced structural integrity.

“The ProHead products provide a range of benefits,” Shuler said. “Its proprietary offset head design allows more nails to nest on a single paper tape strip for greater efficiency, while it is recognized under ICC ESR-1539 to comply with IBC and IRC building codes.”

He noted that ProHead nails are also compatible with and fit in most 30-degree to 34-degree framing nailers. As with over 80% of its fasteners, these products are made at SENCO’s manufacturing facility in Cincinnati, Ohio.

SIMPSON STRONG-TIE

In the construction industry, the tools and materials you choose can make all the difference. Simpson Strong-Tie offers a range of products designed to elevate the performance and appearance of every job.

“With solutions ranging from innovative installation tools to highperformance fasteners, Simpson Strong-Tie ensures that contractors, dealers, and remodelers can deliver quality projects that stand the test of time,” said Andrew Brigham, fasteners group product manager at Simpson Strong-Tie.

|

| The Simpson Strong-Tie Project Pro screw driving tool complements the company’s Quick Drive product line by offering precision and durability for screw installation. |

The company devotes significant research and development to its products that provide ease of use, increased productivity, and increased levels of safety and ergonomic relief. Brigham said solutions such as the Quik Drive auto-feed screw driving systems, Timber Drive structural screw installation system, and Quik Stik rafter/truss tool were engineered with these benefits to the contractor in mind.

“Strong-Drive fasteners are engineered to make structural connections easier for the contractor or installation professional,” he said, noting that Strong-Drive structural screws are made from premium materials and are load-rated and code listed per IAPMO UES ER and ICC-ES, and meet or exceed current IRC and IBC code requirements for most common wood and engineered wood applications.

Brigham said many of the Strong- Drive structural screws, such as the SDWS Timber Screw and SDWH Timber-HEX product lines, are designed and engineered to be solid replacements for lag screws and bolts.

“Lag bolts often require awkward and time-consuming two-sided installations, one side for pre-drilling and installing the bolt and the opposite side for securing the nut,” he said. “SDWS and SDWH products install from one side and often do not require pre-drilling.”

Recently, Simpson Strong-Tie introduced the Strong-Drive SWD Double-Threaded Screw, which is ideal for securing two wood members together on exterior or interior structural jobs. Brigham said the screw features a chisel point for reduced splitting, a double-thread design and smooth, unthreaded mid-shank to secure wood members tight, and a compact head for low visibility.

“Available in an assortment of lengths, the SWD screw is a game changer that can be used in a variety of applications such as knee bracing, fastening beam to post, beam to joist, or guardrail to post with ease, replacing traditional connector hardware,” he said.

In terms of productivity tools, Brigham cited the Simpson Strong- Tie Project Pro screw-driving tool and how it complements the company’s Quik Drive product line by offering precision and durability for screw installation. It is designed to manage high volumes of screws with minimal fatigue.

“With its lightweight, ergonomic design and ability to connect to most cordless drills and impact drivers, Project Pro reduces user strain during extended work sessions, promoting both comfort and efficiency on the job site,” Brigham said.

He noted that Simpson Strong-Tie will continue to provide comprehensive, high-performance solutions that address all aspects of construction.

“Whether you’re building for residential or commercial plans, Simpson Strong-Tie has the solutions to ensure the project is completed efficiently, securely, safely, and beautifully with high-quality products,” Brigham said.

LEARN MORE

This article originally appeared in the June/July 2025 issue of Contractor Supply magazine. Copyright, 2025 Direct Business Media.