|

Pneumatic nailers and staplers transformed the construction industry many years ago. Today, they are among the most common fastening tools found on a jobsite. With the continued emphasis on productivity, it is critical that contractors have tools which can reliably and repeatedly drive fasteners into even the hardest of materials.

Demand has only risen with the increase in infrastructure development and construction. The competitive market for these tools continues to intensify with domestic and global manufacturers offering a diverse set of products.

The industrial nailer and stapler market was valued at $1.06 billion in 2023 and is expected to reach $1.38 billion by 2029. Reports show that the North American region continues to hold the largest market share and is expected to continue to grow.

Contractors continue to look for options that deliver the maximum combination of speed, productivity and reliability in the field or in highproduction environments. Manufacturers are focusing on lightweight, ergonomic designs with enhanced safety features, ensuring compliance with industry regulations.

Technology advancements have led to lighter weight designs for air compressors, leading to easier portability around jobsites. In addition, several manufacturers have made strides with cordless battery models that are even more mobile, while retaining the performance of their pneumatic counterparts.

The increased emphasis on efficiency and flexibility in construction and woodworking has supported the surge in battery-powered nailers and staplers.

SENCO

“At SENCO, we’re seeing a variety of trends and evolutions in the pneumatic tool category, some driven by advances in technology and others by customer expectations,” said Brandon Groves, product manager for SENCO’s stapler fastening systems.

One significant trend has been the increased adoption of cordless pneumatic tools because of their flexibility and convenience for certain applications. He said another shift has been toward more ergonomic and lightweight tool designs that are easier for operators to handle, reduce fatigue and improve productivity.

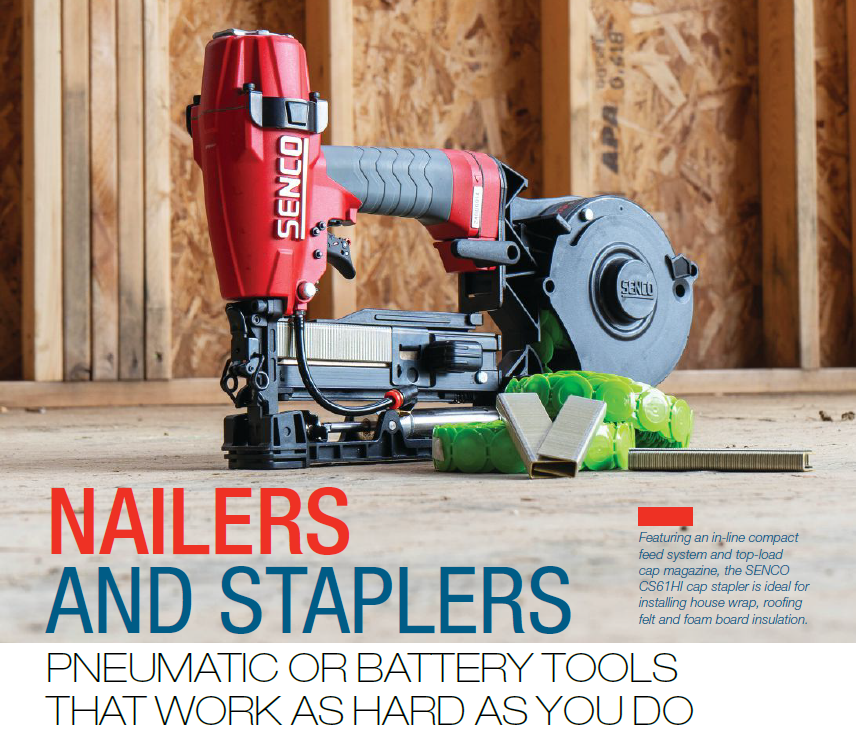

Groves said an example of the latter is SENCO’s new cap stapler, the CS61H1 for house wrap, roofing felt and foam board applications.

“Its rugged, top-load, in-line magazine design was driven by detailed input from industrial customers such as manufactured housing suppliers who put their tools to the test on a daily basis and are preoccupied with performance and durability,” he said.

The CS61H1’s in-line compact feed system and top-load cap magazine secure fastener components while providing optimal line of sight and balance for better maneuverability. Weighing in at only 4.5 pounds, the tool also features heavy-duty door components and wear guards to protect caps and staples from compromise during operation, especially in harsh environments.

|

“As we review and evolve our line of pneumatic products, SENCO is always looking for ways to enhance both durability and ease-of-use, in line with our customers’ expectations,” Groves said. “The CS61H1 is an excellent example of how the voice of the customer can help drive tool designs.”

BECK AMERICA

As a provider of tools and fasteners in the construction industry, Chad Giese, national sales and products manager for BECK America said they are witnessing a complex landscape for general construction trades and the tool sector.

“This year we anticipate slow but steady growth, particularly in areas where automation and innovation are taking center stage,” he said.

The beginning of 2025 has been gradual for both commercial and residential construction. In the commercial sector, numerous projects are poised to launch, alongside the establishment of new manufacturing facilities that promise long-term growth. Conversely, Giese said the residential building sector has faced challenges due to overbuilding, resulting in a slowdown as existing inventory is sold off. However, residential builders are now prepared to invest in building products as inventory levels decrease.

“One of the primary hurdles we currently face is fluctuating interest rates,” he said. “A decrease in rates could pave the way for sustained growth, especially as more people migrate to rural areas.”

Additionally, labor shortages continue to pose significant challenges for contractors, construction companies, and industrial facilities.

“We are also observing ongoing consolidation within the distribution sector,” Giese noted. “Coupled with the challenges of rising material costs and tariffs, these issues have sparked numerous pressing discussions and trends in the industry.”

eering advancements in ecological and renewable construction and automation.

“Our Lignoloc line of FASCO tools, which features the world’s first pneumatically driven wooden nail, is leading the way in making sustainable building practices more accessible,” Giese said. “In the automation realm, we are enhancing our modular head solutions for robotic applications, including nailing and stapling.”

BECK America’s INMOTION handheld carriage is also gaining traction,

|

|

BECK is driven by innovations such as the first pneumatically driven wooden nails with the Lignoloc system or the FASCO INMOTION handheld carriage for seamless |

To address these challenges, BECK America remains committed to pion thanks to the introduction of FASCO adaptable tools designed for seamless inline nailing and stapling.

“By providing innovative solutions to combat labor shortages, we empower businesses to maintain growth and produce consistently high-quality products,” he said.

In addition to expanding and innovating its current product lines to align with the evolving construction landscape, BECK America also is redesigning its fine wire staplers.

“This initiative aims to deliver a more robust and durable stapler than the market has previously seen,” Giese said.

Going forward, he noted that collaboration with builders and contractors will be essential, enabling BECK America to understand their needs and develop solutions to address them.

“Our unwavering emphasis on innovation, durability, and efficiency underscores our commitment to helping the construction industry achieve excellence,” he said.

LEARN MORE

This article originally appeared in the June/July 2025 issue of Contractor Supply magazine. Copyright, 2025 Direct Business Media.