|

Drill bits and their cousins, step bits, taps and annular cutters continue to raise the bar for performance across the board. Manufacturers continue to invest in ways to improve speed, tool life and precision. These companies continue to make an effort in driving you to perfection.

PFERD TOOLS

Demand for specifically high-performance end mills and drills is growing and will continue to do so. Investments in manufacturing efficiency in the automotive, aerospace, and agriculture industries are driving the need for high-performance tools for stationary applications.

|

| PFERD TOOLS’ line of sold carbide end mills for stainless steel and other materials is application specific and designed for productivity, accuracy and long tool life. |

“Emerging technologies and innovations are also driving the growth in demand for high performance cutting tools,” says Scott Gast, carbide cutting tool specialist at PFERD TOOLS.

He notes that a big misconception in the industry is that all end mills and drills are the same, when in reality, material- and application-specific solutions are required.

“For me personally, I’m most excited about our industry’s role in getting us to outer space,” Gast says. “Manufacturing space-worthy aircraft for this millennium is an incredible challenge that requires material-specific cutting tools with unique geometries designed specifically for aerospace.”

He also notes that PFERD TOOLS continues to expand its role as a comprehensive source for metalworking solutions.

PFERD TOOLS acquired a majority stake in Silmax SpA, a premier Italian cutting tools manufacturer, in 2024.

“We are fast-tracking our focus on solid carbide tools,” Gast says. “Our entry into the cutting tools category is backed by the same engineering rigor, material science, and performance standards that made us a leader in abrasives.”

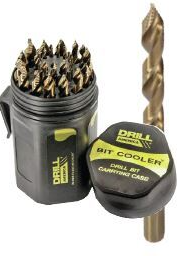

DRILL AMERICA

Over the last five years, Drill America has seen consistent growth.

|

| Stepped Point cobalt drill bits from Drill America, start easier, drill faster, increase lifespan and reduce heat compared to standard drill bits. |

Ellito Barnett, president of Drill America, says the industry has not changed that much, in that cost, delivery and quality remain the three things that shape it.

Barnett notes that a common misconception is the understanding of how difficult it is to produce quality cutting tools. It comes down to quality control and ensuring the correct steel, hardness, fluting and pointing.

“Those are all the things we have to work on and monitor consistently,” he says.

Overall, Barnett says Drill America’s general strategy has not changed.

“We will continue to be America’s tool connection and always be a partner to our distributors through price, quality and delivery,” he says.

LEARN MORE

This article originally appeared in the October/November 2025 issue of Contractor Supply magazine. Copyright 2025, Direct Business Media.