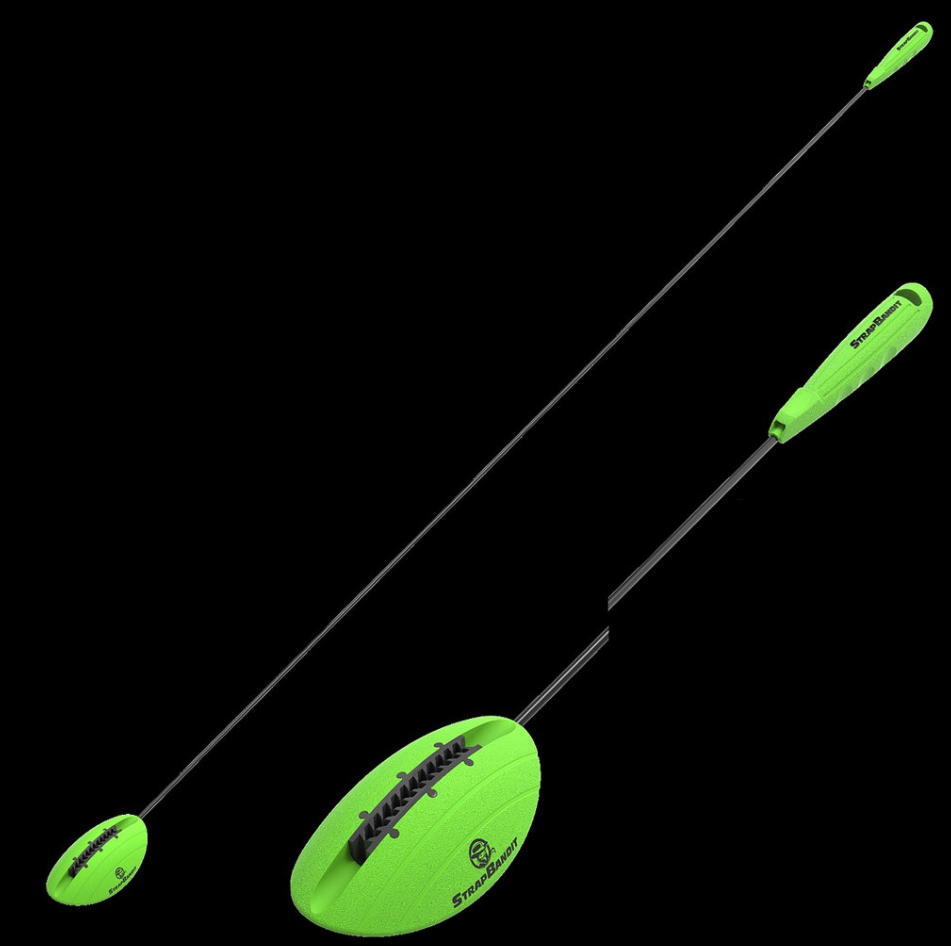

StrapBandit Pallet Threading Tool

|

|

StrapBandit, an innovator in the pallet threading tools market, will debut its new solution in the Teknika Strapping Systems booth (S-7128) during PACK EXPO 2017 in Las Vegas. Known as pallet threading, pallet strapping, and pallet lacing, the process of running the strap through the pallet, for bulk shipping and load securement, has been around for more than a century but has seen little improvement over the years. The result is reduced efficiency and potential employee health risks.

The StrapBandit is designed to simplify the pallet strapping process while improving efficiency and allowing the worker to stay in a more natural and upright position. For companies with ongoing pallet strapping needs, in markets like warehousing, supply chain logistics, manufacturing, and freight shipping, the StrapBandit can deliver a clear bottom-line improvement.

"Broomsticks, branches, cardboard tubes and PVC pipes; I’ve seen many makeshift and commercial tools used for this task, but none that were purpose-built to address the entire problem," said Matt Payne, president, StrapBandit. “All of those tools – homemade or purchased – require the worker to get down on their knees or bend over in an unnatural position. The end game is a health risk that could result in a workmen’s compensation claim due to a repetitive stress injury.

"They also tend to get snagged on the pallet, reducing speed and efficiency. After years of watching this problem go unaddressed, I designed a solution that was easy to use, allowing the worker to stay upright and the tool to traverse the pallet without getting snagged – the StrapBandit was born.”

Exceptional Engineering

From head to handle, the StrapBandit is designed to make the threading process fast, efficient and safe. The durable head threads all common pallets and crates without getting stuck. Its unidirectional cleat easily and securely holds the strap. The device is capable of delivering nearly all plastic and corded strapping, and its composite rod easily flexes to slip strapping through a 48” pallet, without having the worker bend over, even in spaces as tight as 12 inches.

“With the kneeling, bending and do-overs, existing tools can take 10-30 seconds per strap to be attached and released. A hundred straps can take up to 50 minutes to thread. The StrapBandit can handle the same hundred straps in about 9 minutes. That's a massive increase in efficiency. When combined with the lowered safety risks, the tool delivers significant value to our customers with a real impact on their business,” continued Payne.

See the StrapBandit in Action: http://bit.ly/StrapBanditVideo