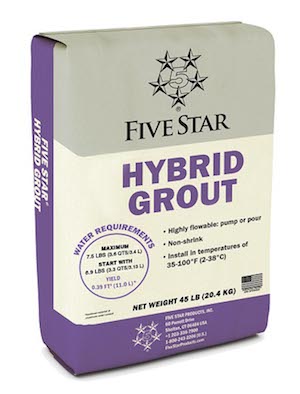

Five Star Products Hybrid Grout

Five Star Products has engineered a versatile grout material for supporting machinery and applications requiring precision alignment. This cement-based, nonmetallic, non-shrink grout offers superior compressive strengths that rival epoxy-based grouts without the added expense.

Five Star Products has engineered a versatile grout material for supporting machinery and applications requiring precision alignment. This cement-based, nonmetallic, non-shrink grout offers superior compressive strengths that rival epoxy-based grouts without the added expense.

Formulated with Air Release Technology to increase the durability of the hardened concrete, it offers a 95% effective bearing area (EBA), meaning less voids and a better bond. The smooth consistency of Hybrid Grout results in optimal flowability for both pumping or pours.

Five Star Products' new Hybrid Grout performs impressively as a multi-purpose product over a wide temperature range of 35-100°F (2-38°C). As a fluid grout meeting ASTM C1107, it can be used to grout anchors and dowels. Its non-shrink characteristics make it stable and capable of handling load transfers and to support tanks, vessels, wind turbines, compressors and turbo equipment.

According to Five Star Products’ Crysta Abell, Market Manager, “Our new Hybrid Grout clearly offers so many solutions. This product is ideal for impact resistant applications, heavy machinery and equipment, high operating temperature conditions, sulfate resistance and high load anchors and dowels. Finally, there is a grout formulation that addresses all of these areas!“

As with all Five Star products, Hybrid Grout installations are supported by highly professional onsite assistance on demand and on time. When necessary, experienced field engineers, backed by a veteran tech support team, are dispatched to work together with customers right at the jobsite.

Visit Five Star Products at the 2018 World of Concrete, Exhibit # S11439, January 23-26, 2018.